Case / DANA

DANA achieved their goals and are ready to meet future challenges with the AGV.

Challenge

Achievement

Solution

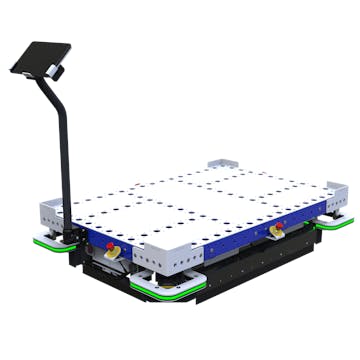

DANA in Mexico, is a world-leading manufacturer and distributor of automotive front and rear axles. They had been looking to develop their intralogistics processes and increase internal efficiency. By replacing old and out-dated industrial carts with our AGVs, they achieved their goals and are ready to meet future challenges.

The AGV was an optimal solutions for DANA

Transportation methods play an essential role in a warehouse. It doesn’t only impact safety and ergonomics but also the efficiency of the material flow and overall profitability. DANA had been using manual transportation when transporting materials between different areas within their warehouse in Mexico. Manual transports are the most basic form of transporting materials, but also the least efficient and ergonomic. When discussing how they move materials, what processes they have, and their goals with FlexQube, the conclusion to add more automation was the optimal solution for DANA to meet their current orders and goals.

Easier and more efficient effective transportations

Our automated concept, the AGV, was implemented. Together a design, customized after DANAs materials, routes, and aisles, was developed. One of the AGVs many functions is the possibility to install different routes and stations. That made it easy for the operators to control the cart and gave them great freedom to choose to which station the AGV should go to next or set a fixed route with.