Signify

Eliminating foot traffic with accessible & user-friendly automation.

Challenge

Achievement

Solution

“So on average, we are looking at about a 10-15 minute savings for each line, having 10 lines out there that can mean up to 150 mins or 2.5 hours. Over the course of a week when you begin adding all of that up, you start to see how an operator’s expertise isn’t being leveraged how it should be.”

– Sturgis Kyle, Engineering Manager Siginify in Pennsylvania, USA

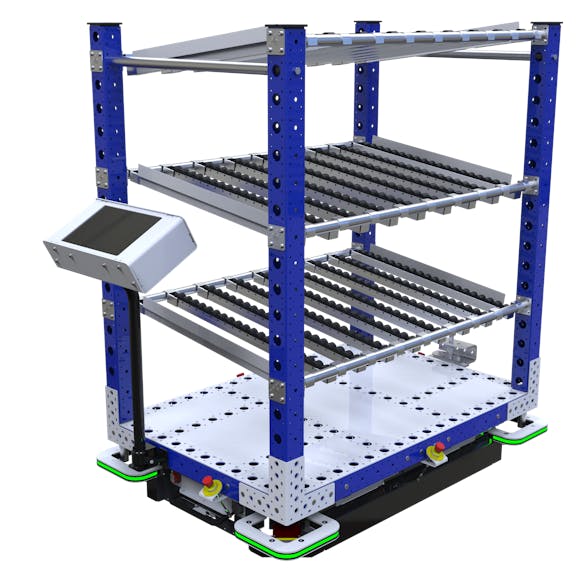

Giving employees their time back

One of the challenges that needed to be addressed was ensuring that employees were given more time to complete their tasks on the manufacturing floor, essentially giving time back to the employees. The key theme to be able to fulfill this was to eliminate single part transportation. Using the AGV to automate transportation through the facility improved the need for the operators to move throughout the facility. On average 10-15 minutes per line was saved per day using the AGV. Multiply this by 10 lines and the days per week and this turns into a considerable amount of time given back to the employees.

Launched the AGV quickly & easily

One added benefit that wasn’t anticipated by using the AGV was how quickly & easily it went from unboxing to in use. Signify Manufacturing Engineer Michael Levengood states “What surprised me most about the AGV was its ease of use. Even the unboxing process to be able to set it up that quickly and get it working, laying out the tape, to it slowing down on different colors. It’s just been a breeze to use, from programming to actually operating it.” Having the AGV programmed through an android operating system provided a fast onboarding process for Signify and meant that their operators on the shop floor were already familiar with the software.