Kit Carts & Specialised Solutions

A kit cart is most often used as a form of material presentation. Kit carts are used in particular along assembly lines, workstations and service areas. Kit carts allow the facility or factory to produce a kit of materials and tools for the assembler along the assembly time.

-

![Shelf Cart – 2870 x 1260 mm]()

Shelf Cart – 2870 x 1260 mm

Q-100-0761

-

![B-Frame Engine Cart – 980 x 1120 mm]()

B-Frame Engine Cart – 980 x 1120 mm

Q-100-0753

-

![Stage Cart – 910 x 1610 mm]()

Stage Cart – 910 x 1610 mm

Q-100-0692

-

![Compartment cart 1260 x 840 mm]()

12 level Compartment Cart – 1260 x 840 mm

Q-100-0311

-

![Bin Cart – 1260 x 490 mm]()

Bin Cart – 1260 x 490 mm

Q-100-0783

-

![Tube Cart – 1960 x 910 mm]()

Tube Cart – 1960 x 910 mm

Q-100-0786

-

![Assembly Cart – 30.3 x 24.8 Inches]()

Assembly Cart – 30.3 x 24.8 Inches

Q-100-0785

-

![Compartments Cart for 280 x 120 mm slots]()

Compartments Cart for 280 x 120 mm slots

Q-100-0308

-

![Compartments Cart for 280 x 120 mm slots]()

Compartments Cart for 280 x 120 mm slots

Q-100-0307

-

![Transport Cart – 71 x 85 Inches]()

Transport Cart – 71 x 85 Inches

Q-100-0784

-

![Rack for Wall Panels – 3640 x 1610 mm]()

Rack for Wall Panels – 3640 x 1610 mm

Q-100-0810

-

![Kit Cart – 2310 x 1050 mm]()

Kit Cart – 2310 x 1050 mm

Q-100-0812

-

![Wire bobbin cart – 1330 x 980 mm]()

Wire bobbin cart – 1330 x 980 mm

Q-100-0643

-

![Tube Cart – 3080 x 630 mm]()

Tube Cart – 3080 x 630 mm

Q-100-0955

-

![Worktable Cart – 630 x 840 mm]()

Worktable Cart – 630 x 840 mm

Q-100-0917

-

![Worktable Cart – 490 x 490 mm]()

Worktable Cart – 490 x 490 mm

Q-100-0916

-

![Kit Cart – 1330 x 770 mm]()

Kit Cart – 1330 x 770 mm

Q-100-1042

-

![Compartment Cart – 840 x 630 mm]()

Compartment Cart – 840 x 630 mm

Q-100-0788

-

![Angled Cart – 1190 x 770 mm]()

Angled Cart – 1190 x 770 mm

Q-100-0836

-

![Angled Cart – 1190 x 770 mm]()

Angled Cart – 1190 x 770 mm

Q-100-0800

-

![Kit cart for cardboards – 1240 x 820 mm]()

Kit cart for cardboards – 1240 x 820 mm

Q-100-0912

-

![Air Freight Material Cart – 820 x 1240 mm]()

Air Freight Material Cart – 820 x 1240 mm

Q-100-0928

-

![Shelf cart for cardboard – 1240 x 820 mm]()

Shelf cart for cardboard – 1240 x 820 mm

Q-100-0919

-

![Hanging cart – 1890 x 770 mm]()

Hanging cart – 1890 x 770 mm

Q-100-0942

-

![Bin cart – 1240 x 820 mm]()

Bin cart – 1240 x 820 mm

Q-100-0914

-

![Cart For Trash – 630 x 630 mm]()

Cart For Trash – 630 x 630 mm

Q-100-0897

-

![Cart for Wall Panels – 1610 x 980 mm]()

Cart for Wall Panels – 1610 x 980 mm

Q-100-0809

-

![Kit Cart – 1190 x 770 mm]()

Kit Cart – 1190 x 770 mm

Q-100-0797

-

![Cylinder Cart – 2800 x 840 mm]()

Cylinder Cart – 2800 x 840 mm

Q-100-1020

-

![Stackable Rack Cart – 1820 x 1330 mm]()

Stackable Rack Cart – 1820 x 1330 mm

Q-100-1123

-

![Shadow Board Stand – 1610 x 1260 mm]()

Shadow Board Stand – 1610 x 1260 mm

Q-100-1148

-

![Kit Cart – 70 x 41 inches]()

Kit Cart – 70 x 41 inches

Q-100-0871

-

![Kit Cart – 630 x 630 mm]()

Kit Cart – 630 x 630 mm

Q-100-1152

-

![Cart for Wall Panel – 1750 x 1610 mm]()

Cart for Wall Panel – 1750 x 1610 mm

Q-100-1303

-

![Rack for Bases - 1330 x 1190 mm]()

Rack For bases – 1330 x 1190 mm

Q-100-1145

-

![Transfer station – 840 x 700 mm]()

Transfer station – 840 x 700 mm

Q-100-1106

-

![Shadow Board Cart - 1260 x 1610 mm]()

Shadow Board Cart – 1260 x 1610 mm

Q-100-1294

-

![Kit Cart – 700 x 1330 mm]()

Kit Cart – 700 x 1330 mm

Q-100-1369

-

![Work Table Cart – 1260 x 840 mm]()

Work Table Cart – 1260 x 840 mm

Q-100-1142

-

![Kit Cart – 840 x 2030 mm]()

Kit Cart – 840 x 2030 mm

Q-100-0544

-

![Air Bag cart – 630 x 1610 mm]()

Air Bag cart – 630 x 1610 mm

Q-100-1392

-

![Kit Cart – 1050 x 1680 mm]()

Kit Cart – 1050 x 1680 mm

Q-100-1185

-

![Kit Cart – 1050 x 1750 mm]()

Kit Cart – 1050 x 1750 mm

Q-100-1440

-

![Kit Cart – 1190 x 980 mm]()

Kit Cart – 1190 x 980 mm

Q-100-1317

-

![Transfer Cart – 1330 x 1260 mm]()

Transfer Cart – 1330 x 1260 mm

Q-100-1327

-

![Kit cart – 910 x 1050 mm]()

Kit cart – 910 x 1050 mm

Q-100-1624

-

![Sign Cart – 1330 x 700 mm]()

Sign Cart – 1330 x 700 mm

Q-100-1246

-

![Kit Cart – 1190 x 2520 mm]()

Kit Cart – 1190 x 2520 mm

Q-100-1311

-

![Plate Cart – 1190 x 980 mm]()

Plate Cart – 1190 x 980 mm

Q-100-1140

-

![Kit Cart – 1260 x 840 mm]()

Kit Cart – 1260 x 840 mm

Q-100-1134

-

![Shelf and hanger kit cart – 910 x 2660 mm]()

Shelf and hanger kit cart – 910 x 2660 mm

Q-100-1443

-

![Roller Transfer cart – 840 x 700 mm]()

Roller Transfer cart – 840 x 700 mm

Q-100-1109

-

![Shadow Board Shadow Board Cart - 1260 x 1610 mm- 1260 x 1610 mm]()

Shadow board cart – 1260 x 1610 mm

Q-100-1605

-

![Blower assembly cart – 1540 x 1610 mm]()

Blower assembly cart – 1540 x 1610 mm

Q-100-1604

-

![Side panel cart – 1400 x 1470 mm]()

Side panel cart – 1400 x 1470 mm

Q-100-1591

-

![Panel Kit Cart - 1050 x 1680 mm]()

Panel Kit Cart – 1050 x 1680 mm

Q-100-1823

-

![Work table – 420 x 630 mm]()

Work table – 420 x 630 mm

Q-100-1355

-

![Compartment cart – 1260 x 1330 mm]()

Compartment cart – 1260 x 1330 mm

Q-100-1405

-

![Kit cart – 840 x 1470 mm]()

Kit cart – 840 x 1470 mm

Q-100-1657

-

![Tugger Fixture – 910 x 1960 mm]()

Tugger Fixture – 910 x 1960 mm

Q-100-1645

-

![Panel cart – 1470 x 1470 mm]()

Panel cart – 1470 x 1470 mm

Q-100-1618

-

![Cart for Doors – 1470 x 1540 mm]()

Cart for Doors – 1470 x 1540 mm

Q-100-1811

-

![Roller cart – 770 x 490 mm]()

Roller cart – 770 x 490 mm

Q-100-1209

-

![Assembly Table – 770 x 2170 mm]()

Assembly Table – 770 x 2170 mm

Q-100-1697

-

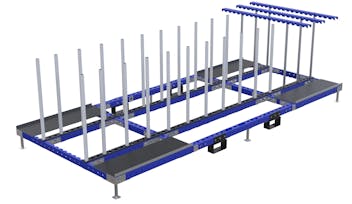

![Kit cart – 1330 x 3920 mm]()

Kit cart – 1330 x 3920 mm

Q-100-1677

-

![Tool kit cart – 630 x 770 mm]()

Tool kit cart – 630 x 770 mm

Q-100-1671

-

![Transfer Cart – 1190 x 1260 mm]()

Transfer Cart – 1190 x 1260 mm

Q-100-1456

-

![Kit Cart for Pallet Collar – 820 x 1240 mm]()

Kit Cart for Pallet Collar – 820 x 1240 mm

Q-100-1558

-

![Compartment cart – 910 x 910 mm]()

Compartment cart – 910 x 910 mm

Q-100-1760

-

![Mobile Workstation Cart- 820 x 1240 mm]()

Mobile workstation cart – 820 x 1240 mm

Q-100-1648

-

![Kit Cart - 1050 x 2310 mm]()

Kit Cart – 1050 x 2310 mm

Q-100-1696

-

![Plate Cart – 1260 x 1890 mm]()

Plate Cart – 1260 x 1890 mm

Q-100-1597

-

![Kit Cart – 980 x 1820 mm]()

Kit Cart – 980 x 1820 mm

Q-100-1716

-

![Cart for Rolls – 1260 x 2170 mm]()

Cart for Rolls – 1260 x 2170 mm

Q-100-1570

-

![Kit Cart – 1050 x 1330]()

Kit Cart – 1050 x 1330

Q-100-2088

-

![Bin Cart – 840 x 1050 mm]()

Bin Cart – 840 x 1050 mm

Q-100-1795

-

![Kit Cart – 840 x 1680 mm]()

Kit Cart – 840 x 1680 mm

Q-100-1875

-

![Shadow Board Cart – 770 x 910 mm]()

Shadow Board Cart – 770 x 910 mm

Q-100-1873

-

![Rack for Pallets 1260 x 1750 mm]()

Rack for Pallets 1260 x 1750 mm

Q-100-1876

-

![Roller Cart – 630 x 1470 mm]()

Roller Cart – 630 x 1470 mm

Q-100-1911

-

![Pallet Cart - 1260 x 1260 mm]()

Pallet Cart – 1260 x 1260 mm

Q-100-1293

-

![Cart w. Hangers –1050 x 1260 mm]()

Cart w. Hangers –1050 x 1260 mm

Q-100-1927

-

![Daughter cart – 980 x 1260 mm]()

Daughter cart – 980 x 1260 mm

Q-100-1960

-

![Kit Cart - 630 x 980 mm]()

Kit Cart – 630 x 980 mm

Q-100-1952

-

![Cable Transport Cart – 980 x 1890 mm]()

Cable Transport Cart – 980 x 1890 mm

Q-100-1951

-

![Refrigerant Lines Cart – 910 x 1820 mm]()

Refrigerant Lines Cart – 910 x 1820 mm

Q-100-1970

-

![Door Cart – 1680 x 2170 mm]()

Door Cart – 1680 x 2170 mm

Q-100-1967

-

![Adjustable Height Work Table – 630 x 1260 mm]()

Adjustable Height Work Table – 630 x 1260 mm

Q-100-1983

-

![Kit cart – 770 x 840 mm]()

Kit cart – 770 x 840 mm

Q-100-1999

-

![Reel Rack – 1050 x 1750 mm]()

Reel Rack – 1050 x 1750 mm

Q-100-1998

-

![Rotating Removable Shelf Cart – 1470 x 1470 mm]()

Rotating Removable Shelf Cart – 1470 x 1470 mm

Q-100-2017

-

![Hanger Cart – 700 x 1260 mm]()

Hanger Cart – 700 x 1260 mm

Q-100-2037

-

![Shelf Kit Cart – 1260 x 2590 mm]()

Shelf Kit Cart – 1260 x 2590 mm

Q-100-2044

-

![Kit Cart – 630 x 1260 mm]()

Kit Cart – 630 x 1260 mm

Q-100-2050

-

![Kit Cart – 630 x 980 mm]()

Kit Cart – 630 x 980 mm

Q-100-2049

-

![Extendable Shelf Cart – 1260 x 2730 mm]()

Extendable Shelf Cart – 1260 x 2730 mm

Q-100-2045

-

![Kit Cart – 840 x 1260 mm]()

Kit Cart – 840 x 1260 mm

Q-100-2068

-

![Frame For Lift Table – 840 x 3220 mm]()

Frame For Lift Table – 840 x 3220 mm

Q-100-2077

-

![Crank Shaft Cart – 2520 x 700 mm]()

Crank Shaft Cart – 2520 x 700 mm

Q-100-0974

-

![Roller Cart – 1050 x 560 mm]()

Roller Cart – 1050 x 560 mm

Q-100-0973

What is a Kit-Cart?

A kit cart is most often used as a form of material presentation. Kit carts are used in particular along assembly lines, workstations and service areas. Kit carts allow the facility or factory to produce a kit of materials and tools for the assembler along the assembly time. This means that the assembler/operator no longer has to look for different components and tools. This makes the assembly process much smoother and easier for the assembler, which in turn improves overall efficiency and productivity within your plant.

Contact FlexQube to Learn More

Why buy a FlexQube Kit-Cart?

FlexQube enables customers to create totally customised carts for their needs, according to the materials and according to their work processes. All of our carts are designed and constructed with high quality steel, so our kit carts have a much higher load capacity in comparison to more traditional tube and joint systems.

With more and more end-product variants available to manufacturers nowadays and especially OEMs within the automotive industry, there is not enough room to store all the different part numbers along the assembly line at the same time. Therefore, components need to be provided just in time or in sequence or in smaller batches using e.g. kit carts or carts where you store different part numbers but in smaller quantities. Many times, this is referred to as naked material presentation. This means that the components are presented to the operator on the production line or in the workstation without any packaging, plastic coverings or are taken out of the boxes and placed in a position where the operator can just pick up the part without spending time on unwrapping the items.

Kitting parts means that more of the work related to material handling is transferred back to the warehouse or logistics employees. Space and speed on the assembly line are crucial which means that the operators and assemblers cannot spend any unnecessary time unwrapping parts or opening cardboard boxes. They must concentrate on fitting parts on end-products and instead leave material handling tasks to the logistics staff. Kit carts are an useful tool in all this and the need for flexible solutions is of course great since shapes, dimensions, quantities, etc. will change over time. Using a flexible and modular system like the one from FlexQube makes it possible to adjust and adapt kit carts to constantly changing needs.

FlexQube has cantilever-style carts to hold pipes, rods, wire ropes or hoses. We have delivered these solutions to a variety of industries including heavy industrial equipment companies like JLG Industries, Cummins and Doosan Infracore. Other references for kit carts are Whirlpool and Isringhausen.

Kit carts mean that the carts are used to transport a limited amount of parts to the assembly operations, in some cases also in sequence meaning that the parts must be put onto the cart in a specific order to make sure the operators pick the right part for the right product. It is also of course important to set up the kit cart in an efficient way to make sure the picking time both in the warehouse but even more important on the assembly line, is kept to a minimum.

By gathering information about batch sizes, sequences, mixing of parts and other parameters, FlexQube can help customers design and adapt the perfect kit cart. A kit cart with built in flexibility for upcoming changes in component design and manufacturing mix etc.

A kit cart can be used for one specific type of component or as an all-in-one kit cart for multiple different components. They can vary in size and complexity. If the kit cart holds very large or heavy parts, it is important to consider the use of lifting equipment and to make sure they can access the component along the assembly line.

In the kit carts category on our Solutions Library platform you will find several different designs that can help you bring the material to the operators in a better and quality assured manner.