Case / Siemens

Siemens gets started with automation!

Challenge

Achievement

Solution

“We got started with a future factory.

We have automation now in our factory, and now we can build on it; we can bring in more robots we can be created and innovative with how we can use this different technology in our factory.“

– Kim Howe, Logistics Manager at Siemens Mobility in Georgia, USA

Siemens got started with automation!

One of the most significant benefits that Siemens could take away from implementing the AGV products into their facility was that they got started. They were able to map out the project, assess their needs, and implement an automation project, which was fully automated. Automation is a journey that will never stop, so taking the first steps can be the most difficult and the most daunting. Still, now those complex steps are over for Siemens.

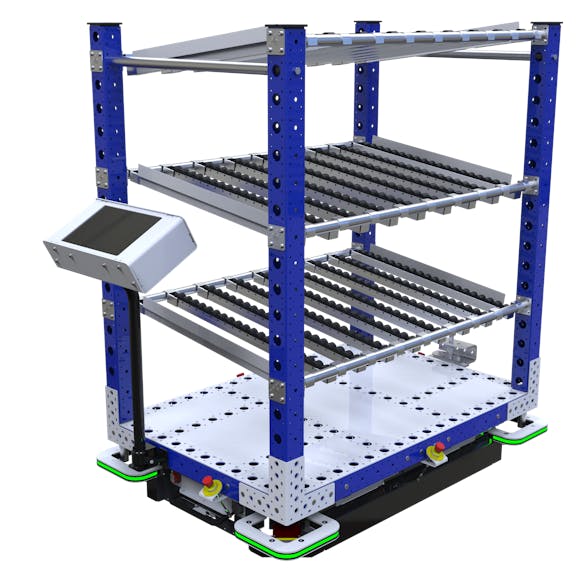

Robust Automation. Simple Implementation.

When it comes to automation in a manufacturing environment, consistency and robustness are a must. The automation needs to be reliable to turn up and deliver every time, and with the AGV this is assured. Siemens was able to implement a solution that can be depended on every single transport. The AGV also comes without the frustrations of typical automation implementations. The AGVs needed no extra IT infrastructure, and the implementation was completed in a minimal amount of time.