How it works

Modular solutions.

Your materials constantly change… Shouldn’t your cart?

How does it work?

FlexQube® creates solutions based on your requirements to suit your specific needs while providing robust, modular and ergonomic solutions for material handling.

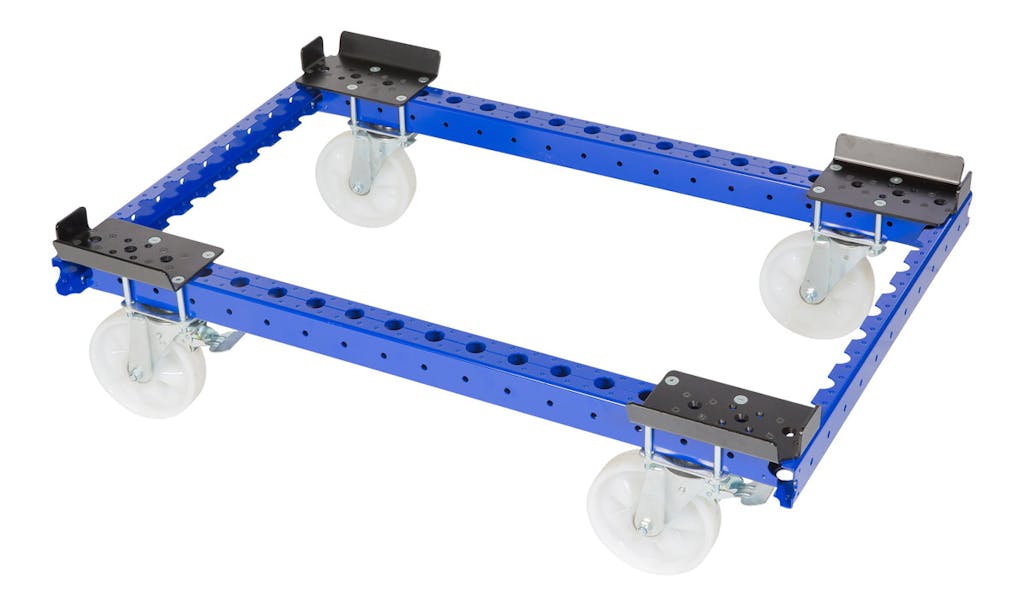

7 cm Design Base

The FlexQube system is based on the number 7. All FlexTubes™ and FlexBeams™ come in length intervals of 7 cm and the distance between interfaces is 7 cm. Two FlexBeams™ create a 7 x 7 cm square cross-section and two FlexQubes™ form a 7 x 7 x 7 cm cube. FlexPlates™ and Flexqube™ have the same interface and are therefore easily placed anywhere on FlexBeams™ and FlexTubes™ to connect them.

Basic Design

The basic design of a FlexQube cart is a base frame with a top structure attached to it. The bottom frame is usually equipped with a set of casters, handlebars, tow bars and a brake.

Each of these attachments is specified and located optimally to suit the actual application and the ergonomic requirements. The dimensions of the base frame are adapted to your actual needs.

Customisation

The top structure is optimised for the type of cargo to be carried. It can be anything from a solid steel flatbed for heavy pallets to an advanced rack for a model-specific assembly kit. The top structures can be dependent on whether they will be used for material transport or for presenting material to operators for picking.

Transportation

FlexQube carts can be easily adapted to any transportation. Our carts can be transported manually with a handlebar, towed with a tow bar, lifted with a forklift truck using fork pockets or automatically transported using AGV attachments. The choice is yours.

Casters

At FlexQube we aim to ensure that all of our material handling carts are designed with the highest quality casters on the market. Different casters can have a major impact on the overall function of your cart and its success in your material flow.

Q-100-8305

KLT Cart - 1260 x 840 mm

Product

Q-100-8306

KLT Cart - 1260 x 630mm

Product

Q-100-2504

Hanging Cart - 910 x 2030 mm

Product

Q-100-0112

Pallet Tugger Cart - 1260 x 1260 mm

Product

Q-007-1424

Shelf Tugger Cart – 840 x 1680 mm

Product

Q-100-0609

Shelf Cart – 1400 x 1040 mm

Product