3 Tips to Integrating Automated Material Handling Equipment in Your Facilities

The benefits of an automated shop floor have been one of the major selling points behind making the move to Industry 4.0. These benefits include more effective production cycles, reducing operational costs, and reducing material waste.

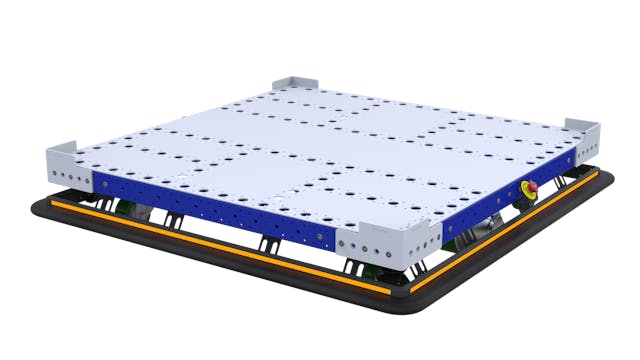

To take advantage of these benefits, a shop floor’s layout must be efficiently organized, and an automated material handling equipment system has an important role to play. So, if you are considering automating the material handling equipment in your facilities, here are some timely tips on getting started.

Integrate Preventive Maintenance Measures – The longevity of your material handling system and the equipment in it relies on how it is used. Therefore, to forestall equipment breakdown which, in turn, leads to production downtime, a maintenance policy must be put in place. For automated material handling equipment, the preventive measures consists of ensuring shop floor routes are debris free, load limits are kept, and AGVs are properly maintained.

In an Industry 4.0 complaint factory, automated material handling equipment should be part of an interconnected device ecosystem. Then the data collected by management software apps can get automated MHEs to run diagnoses and schedule periodic servicing tasks. Putting these preventive measures in place ensure your equipment works optimally for longer durations. So, greater returns on your investment in automated material handling equipment can be achieved.

Ensure Workplace Safety – Although the principle of automating manufacturing facilities and warehouses revolves around eliminating manual labor, humans still operate and oversee smart factories. The safety of those providing manual assistance to automated material handling systems must also be accounted for.

As stated earlier, the planning phase should include feasibility studies on enhancing shop floor safety. To achieve a safe facility where automated material handling equipment is used, safety policies must be put in place and workers must be trained according to this policy. It is a role of thumb that workers must not ride on automated vehicles and the load capacity of this equipment must be adhered to. It also goes without saying that, proper installation and use of a material handling system reduces damage to the materials being transported across the shop floor.

Ensure the Cost is Right – The financial bottom line of every facility determines how long that facility stays in business. Therefore, the cost of installing an automated material handling system and its corresponding equipment must be considered. As a facility manager, the task of ensuring you get the best deal for your material handling requirements falls on your shoulders.

Today, warehouses and factories are the main beneficiaries of automated material handling equipment but in the near future, hotels and healthcare centers will have a lot to gain from automating material handling processes. And from the tips provided here, the task of accurately developing a functional material handling system is a technical one that requires professional expertise. To assess your material handling needs, simply contact a FlexQube professional technician to learn more about the options available to you.