A Guide To The Basics of Successful Material Handling

Last Modified: 2022.08.29

Material handling is essential in any logistics and manufacturing project. The global material handling market is expected to grow at a compound annual growth rate (CAGR) of 8.3 percent to 127.26 billion US dollars in 2025, making it important for companies to pick the proper solution for their projects.

There is a vast selection of material handling solutions, however, a majority of all physical commerce items are transported using tugger trains and carts.This guide will examine the role of tugger trains and carts in material handling and give you an idea of how to implement efficient material handling solutions, including its types, principles, and design.

Find the English Product Catalog here

What Is Material Handling?

Essentially, material handling is a process that includes short distance movement inside the scope of a building, or between the transportation vehicle and the building. It uses various types of equipment such as manual, automated, and semi-automated. In addition,the material handling process involves the movement, protection, storage, and control of materials. This handling process occurs in manufacturing shop floors, warehousing, distribution, and even in material disposal. This is why material handling is an important process in every facility.

Growing Importance of Material Handling Systems

Businesses create place and time utility through the help of material handling. It’s most helpful for retail stores, warehouses, and manufacturing plants. In the job of all production workers, material moving equipment plays a vital role. Operators of these machines use them to conveniently transport items to industrial settings like moving construction goods in building sites.

When it comes to the design, material handling systems have integral structure to efficiently manage the flow of materials between activities of production systems. If there are two activities adjacent to one another, materials can be simply transported. However, for separated activities, more expensive transport trucks will be needed to move the materials.

Using industrial trucks are expensive because of the labor cost of operators plus the negative effect on the production system’s performance when several units are fused together in one transfer batch just to reduce the required number of moving trips.

Ensuring safety in workplaces where material transportation occurs is also a growing need across most industries. This is due to the ease of accidents that occur in facilities. Efficient Material handling processes reduce these accidents. The importance of materials handling can also be simplified as highlighted here:

- To conveniently and safely transport materials across facility floors

- Assist in streamlining work activities and organising factory space

- Reduce accidents in facilities where heavy materials or loads are transported.

Concept of Unit Load and In-Process Handling

Unit load means the item’s single unit, or several units combined as a single unit to maintain integrity. While liquid, gaseous, and granular materials may be moved in bulk, they may also be combined into multiple unit loads through cylinders, bags, and drums. The main advantage is that more items are handled simultaneously. Therefore, it reduces the required number of moving trips while possibly decreasing handling costs, product damage, and loading/unloading times.

In terms of in-process handling, unit loads are received, stored, and shipped for distribution. The process includes determining the weight, configuration, size, and type of the loads. The method and machine used in handling the loads are also involved in the design of unit load. In addition, it covers how the load is formed and broken down during the in-process handling. However, it’s important to keep in mind that unit loads shouldn’t be bigger than the size of production batch in process.

For the distribution part, it’s important to choose the exact unit load before transporting items. This can be challenging since the pallets or containers are only available in specific configurations and standard sizes. Rail boxcars, airplane cargo bays, and truck trailers are restricted in height, length, and width. Also, the feasible pallet or container sizes for loads are limited to the storage rack and warehouse configurations as well as the retail store shelves and customer carton sizes.

Material Handling Types to Consider:

There are two main types of material handling that operators and company owners need to know. And here they are:

1. Manual Handling. This type of handling is where workers use their hands in moving individual containers. They lift, lower, fill, empty, or carry the containers when transporting them. However, this can be hazardous for workers since it exposes them to physical activities where they can be injured. In most cases, workers suffer from sprains and strains in their lower back, upper limbs, and shoulders. Fortunately, there have been ergonomic developments made to reduce the risks in manual handling of containers.

In addition, manual material handling carts refer to handling solutions that are operated and moved manually. These carts are generally equipped with wheels and handle bars for moving and steering the cart. They are the most commonly used carts and can be found in every industry.

2. Automated Handling. Equipment are used in reducing or replacing manual handling of materials when economically and technically feasible. In fact, many of the material handling machines available today are semi-automated due to human operator needs such as driving, unloading, or loading of containers that are challenging and expensive to automate. Thanks to the ongoing improvements in machine programming, sensing, and robotics, there is a move to completely automate the handling of materials.

How to Start, Conduct, and Implement a Successful Material Handling

With the complex processes of material handling needed in moving containers and loads, it’s essential to understand how to start, conduct, and implement a successful material handling project. Using automated equipment has been perceived to be a costly and risky investment. However, this is the best way to save on material handling projects while getting the exact hardware needed in the building site.

When it comes to assessing material handling equipment, physical evaluation is important. It helps in assessing the equipment in order to determine how to best take advantage of them. Start with the original source of the equipment. Consider the specifications, drawings, programs, service records, and spare parts list to make sure the equipment meet your exact needs.

Raw materials play a vital role in the manufacturing industry and service organization. In any business, material handling can be done in several ways depending on the specific requirements of the company. Whether you are choosing the automated or manual process, finding the best tools and equipment is important. Here are some effective tips in using material handling equipment:

- Determine the most appropriate distance that should be covered.

- Facilitate material damage reduction in order to improve their quality.

- Reduce total manufacturing time through well-designed material movement.

- Enhance the flow control of materials.

- Create and encourage hazard-free and safer work conditions.

- Improve efficiency as well as productivity.

- Boost time utilization and equipment usage.

It is critical for every manufacturing company to determine the essence of material handling systems. However, it’s important to understand the need for promoting job development processes and safety. For instance, manual material handling is responsible for increasing health hazards for laborers in the building site. They are most vulnerable to suffer from lower back pain and other physical injuries.

With the globalized and competitive environment, it’s also critical to reduce time and control cost in any material handling management. An effective process typically promotes the following:

- Proper design for the overall facility layout.

- Development method that promotes simplified and improved work process.

- Overall productivity is improved.

- Effective material handling management to reduce production costs.

Of course, it’s also necessary to understand the principles involved in the material handling processes. They include:

- Orientation – this principle promotes assessment of any available system relationship prior to the preliminary planning. It may include an evaluation of the problems and existing methods.

- Planning – when it comes to planning, it should involve the basic requirements, contingency planning, and other desirable alternates.

- Systems – this principle should integrate storage and handling activities that is cost efficiently integrated into the system.

- Unit load – this is the handling of products through unit loads as big as possible.

- Space utilization – encouraging efficient utilization of available space is another excellent principle in material handling.

- Standardization – this principle encourages handling methods standardization for better equipment performance.

- Ergonomic – this recognizes limitations and human capabilities through the design.

- Energy – with this principle, it considers the energy consumption during the handling process.

- Ecology – it should have minimum impact on the ecology.

- Mechanization – this is to encourage efficiency in handling materials.

- Flexibility – equipment and methods should be practical in any condition.

- Simplification – simplified process is better than complex methods as it removes unnecessary movements.

- Obsolescence – this principle encourages equipment preparation policy to economically take advantage of material handling tools.

How to Use Tugger Trains and Carts in Material Handling

With the changing needs of the industries worldwide, businesses also need to keep up with the changes to survive the competition and be able to supply the demands of consumers. When it comes to material handling, change is also constant just like in other industries, so a lot of improvements were made in the material handling aspect. Today, using material handling tools such as Tugger Trains, Tugger Carts, Mother/Daughter Carts, Pallet Carts, Shelf Carts, Rotating Carts, Tilt Carts, Flow Racks, Kit Carts, and Transport Racks are the latest trend.

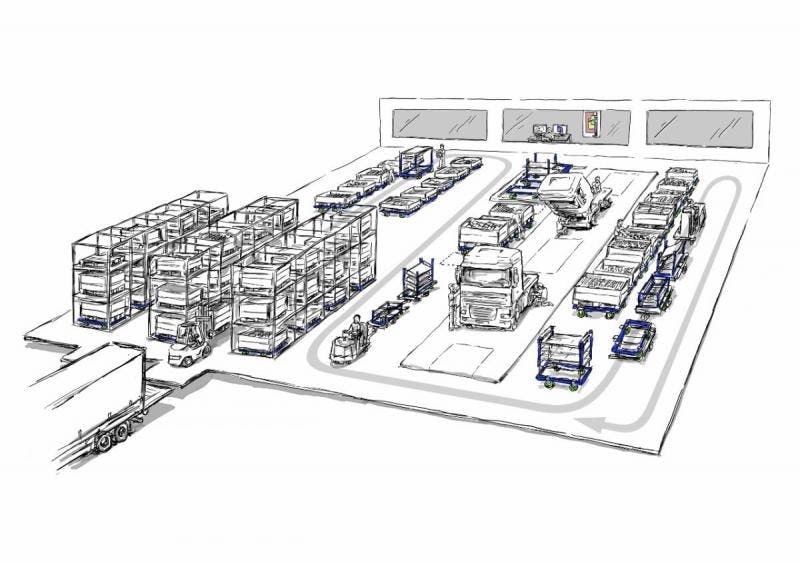

Today, intralogistics processes such as material supply distribution from warehouses to production lines are becoming a big challenge for many factories across the globe. Forklifts don’t seem to be enough to handle material transport requirements, so they are now becoming history in the logistics industry. Carts are currently the star of material handling in Europe, Asia, USA, and Scandinavia.

These flexible carts are not welded to adapt to various scenarios and needs of operators and workers. For many businesses existing today, material carts are simpler and more efficient to use. The design and structure of the FlexQube concept are adaptable to the current needs while it can withstand heavy unit loads. The build of material carts also consists of FlexQube’s core building blocks in standardized dimensions to simplify handling processes.

Here are some of the most common intralogistic projects that help modify the material handling industry:

- building new plants

- launching new products

- improving work stations

- implementing part kitting

- lessening forklift traffic

You’re probably asking yourself right now how these Tugger carts work. That question can be simplified through these product requirements explained below:

- Weight capacity – it’s the total weight of unit loads, or materials loaded to the trains or carts.

- Pay load – weight of carts and loads in train

- Cart footprint – cart size which is connected to the train

- Tracking path – path divergence for the last cart included in the trains

- Turning radius – train path radius when it turns 180 degrees

- Noise level – sound made by the train when in factory operation

- Start force – force required in starting movement of carts

- Push force – force required in maintaining travel speed

- Connect time – time required in connecting a cart to the train set

- Release time – time required in releasing a cart from the train set

- Train setup – number of required carts connected to the train

- Speed limit – speed of train and tow tractor

To help you understand how each carts work and how to take advantage of them, here are some tips for you:

- Tugger trains have multiple cart sizes in the train set with one-way and narrow aisles. They are best used in reducing forklift traffic, increasing flexibility, and saving space.

- The AGVs are integrated carts with AGV in which every part is for one specific product contained by the cart. It is effectively used in reducing manhour, lessening forklift traffic, and saving space at the line side.

- The mother/daughter carts are perfectly designed for transporting four carts simultaneously while placing daughter carts near the assembler. It is the most ideal option in reducing assembler walking, saving space at the line side, and reducing the number of transport trips.

Benefits of Material Handling Systems

The latest developments in material handling systems support the needs of various companies that require handling equipment. With the complex material handling processes, it is truly a great advantage of have a feasible material handling system that adapts to the unique needs of operators and industrial companies.

The following are the helpful benefits of using material carts and trains in transporting containers or unit loads from the warehouse to the building site:

- save money

- increase safety

- reduce downtime

- improve ergonomics

- increase efficiency

- reduce fork transport traffic

- increase capacity

- save space

- increase flexibility

- improve work environment

Whether you are an assembler, production engineer, logistic operator, logistics engineer, maintenance engineer, safety engineer, or the management head, material handling carts and trains are the best options today. Innovative handling equipment improves work efficiency while reducing wastes generated by damage or careless usage.

The ongoing move to Industry 4.0 and a smarter work or manufacturing space is also reliant on proper material handling. Here again, making use of semi-automated or fully-automated systems is the way to go. The benefits of this material handling solution include reducing downtime and accelerating just-in-time delivery and production.

When materials are properly handled, the number of lost or damaged materials is also reduced. In addition, methodical and efficient manner of material handling promotes cleaner work environment. Some may believe that automated equipment is a risky investment, but with proper management, they are more beneficial than other tools and machines used by industries today.

If you’re looking for a similar solution, contact us at sales@flexqube.com

You may also like:

How to start the transition from forklifts to a tugger train system