AGCO is all in on FlexQube

It started with shelf carts in the fabrication area. 100 of them to be more precise. Then, AGCO in Jackson Minnesota started buying components to put together different kit carts by themselves. AGCO ordered parts to assemble 60 kit carts on their own.

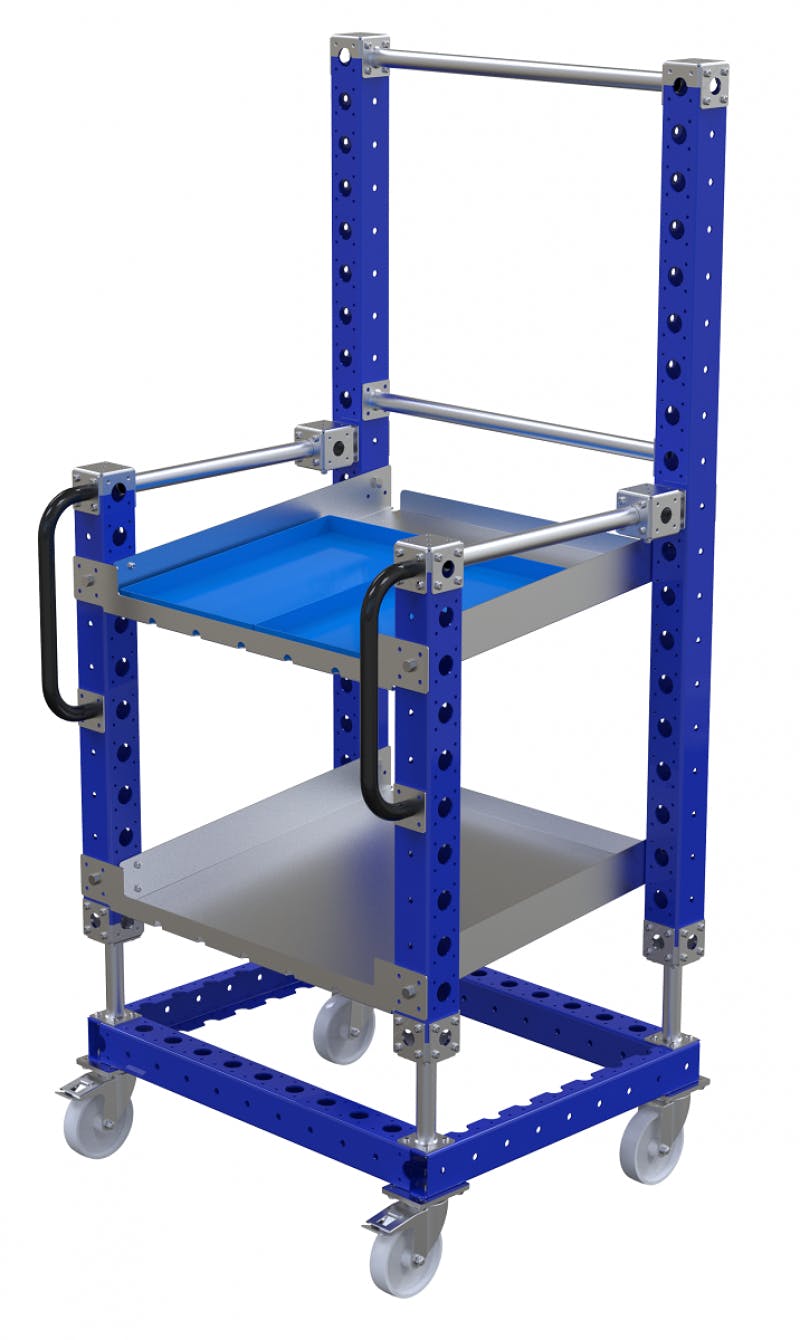

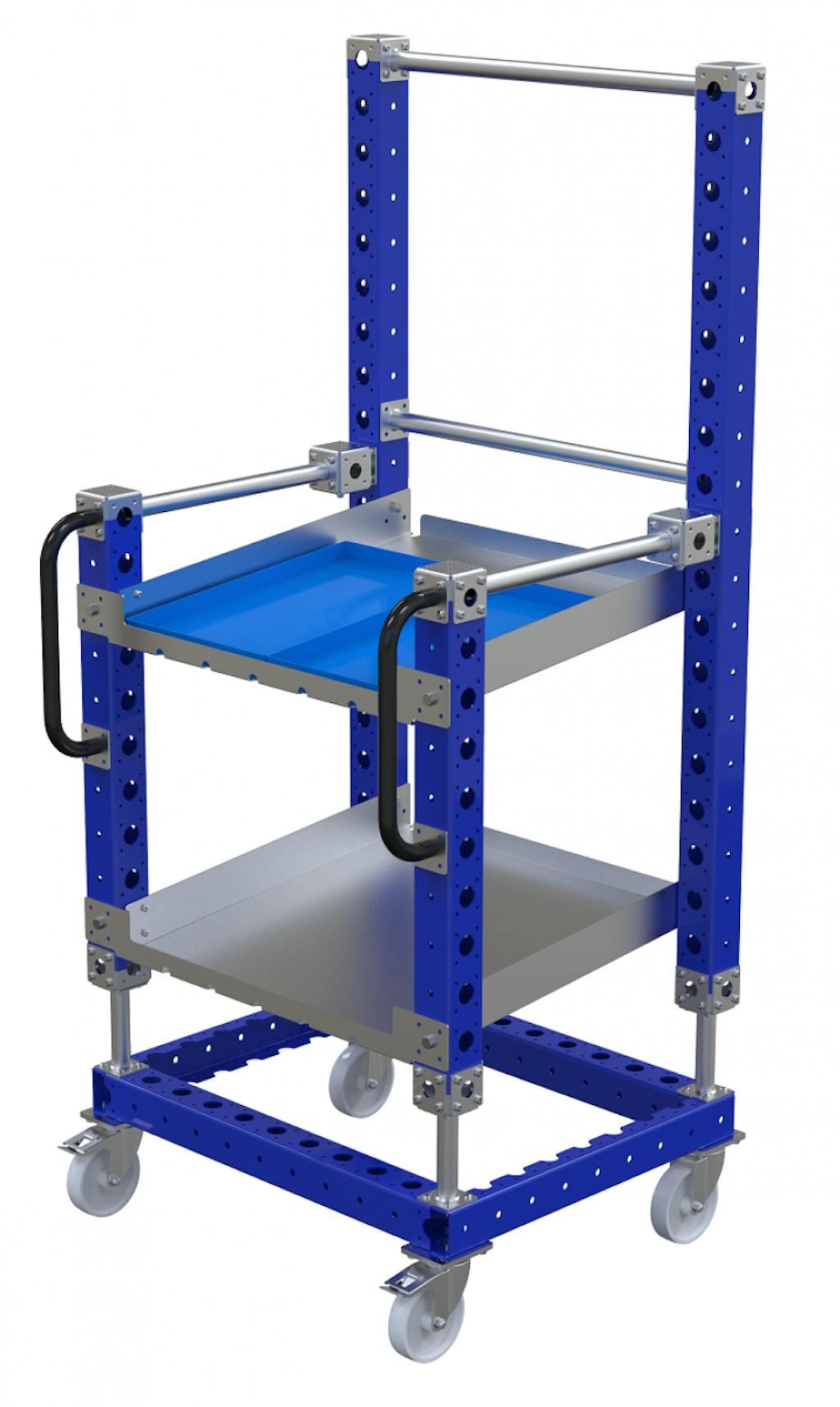

Then we started looking at the assembly area and some new tool carts to replace the current ones they had. By having a Design On Demand session with one of our design engineers AGCO could specify the requirements in a web call during one hour. AGCO decided to order 35 tool carts of that kind to begin with.

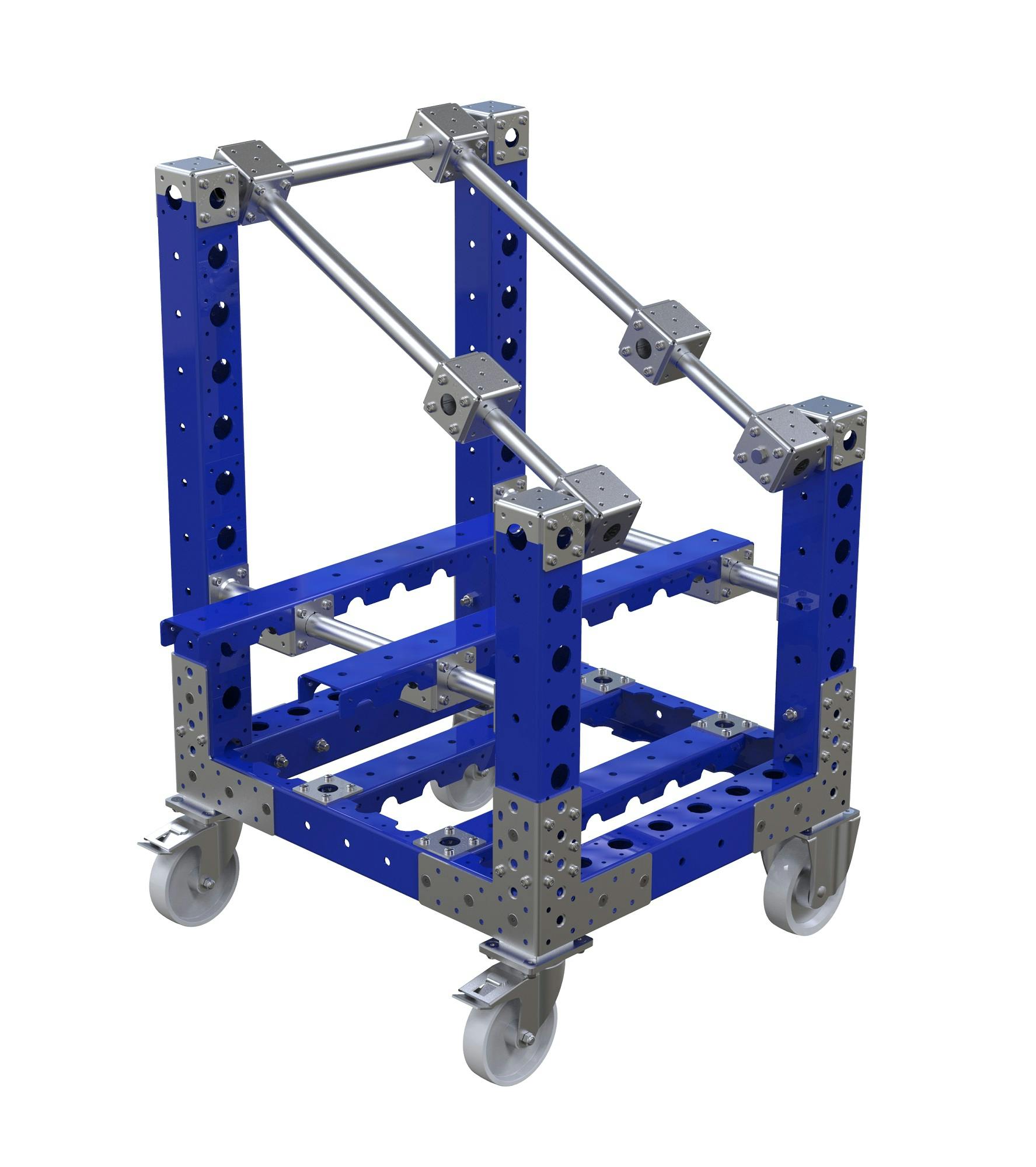

Then some of their managers thought the carts looked so good and worked so great that they wanted the engineers in the assembly area to replace all of their current assembly carts, with FlexQube carts. We did a new Design On Demand session for 9 different cart types. You see the result below. A wide range of different carts for various components that will be mounted onto the AGCO Tractors and Sprayers.

In total this new order is worth $60 000 and consists of 47 carts and a lot of loose components in order for AGCO to put together different solutions by themselves. In our Solutions Library™ they will find inspiration and CAD models.

Read more about a AGCO case study!

Watch our CEO Anders Fogelberg demonstrate the system.

If you’re looking for a similar solution, contact us at sales@flexqube.com

You may also like:

The benefits of tugger carts in lean manufacturing

How to use flatbed carts to improve your material handling