An Interview with FlexQube’s Head Design Manager

An Interview with FlexQube's Head Design Manager

Olof Brown is FlexQube’s Head Design Manager and has been working closely with industrial cart design and the FlexQube concept for quite some time now. Olof works closely with many of our customers in the USA and in particular helps our US sales team to prepare designs and customize the solutions, as well as working on developing the concept with FlexQube’s CTO Per Augustsson. The USA is FlexQube’s largest market and some of that can be credited to Olof’s great design work, which is very focused on problem solving. Olof is very good at being able to meet with customers for only 15-20 minutes and then being able to create a design which matches their needs and this creates alot of value for the customer.

Olof has been very busy and we were happy to ask him some short questions about his design process and his time with FlexQube.

1. How long have you been working with FlexQube as a designer?

I have almost been with FlexQube for 5 years now, and I can’t believe it has been that long, it doesn’t feel that long to me at all.

2. In that time what are some of your favourite designs you have created?

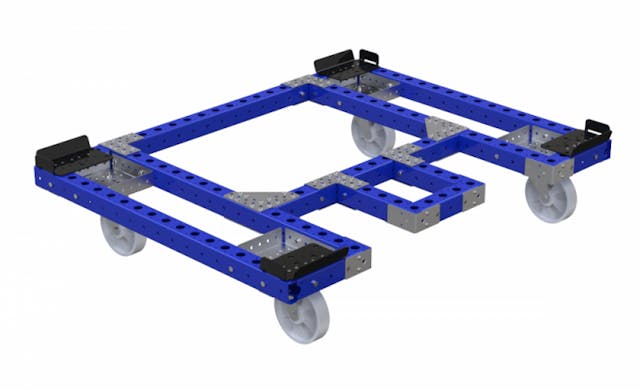

I really love creating the weird customized kit carts that are designed for transporting one particular part or component. Usually with those types of projects the customer has been struggling to find a suitable solution and these solutions provide alot of value to the customer straight away. For example we had a customer who really needed to find a solution to transporting a series of finished seats to the assembly line, in a kit set-up. This helped the assemblers access the materials more easily, but most importantly boosted efficiency in the plant, because more than 2 seats could be transported at a time now. There’s a few designs which have really stood out for me and have a special place in my heart, and you can see them below:

3. What has been the most common cart or cart type in the US market?

Generally, the most common type of solutions are the simplest ones. Pallet and shelf carts have been the most common type of cart in the US so far. However, I do see an increase in custom carts being designed, I think the reason for this is that our customers realize they are able to easily change the carts to match their materials. Prior to this many of our customers would have their carts welded, so they would choose a cart design which could adapt to the most materials, so they could get most value for money. But with FlexQube’s modular concept, the carts can be purchased in one design and easily customized after the purchase for different or new materials. This gives our customers the confidence to actually try a solution which is designed for their materials.

4. What is often a very convenient feature that is often overlooked?

I wouldn’t say there is one specific feature that is often overlooked. It’s our job in the DesignOnDemand™ to present the customer with the different options available and often it’s the other way around. The customer wants all the features included, and in the end we usually take features off due to cost. Therefore, it’s always important to think about what features you NEED to have and which features would be nice to have before you start with the design. This can save a lot of time and it’s easier for us to say how much extra each “nice to have” feature would add to the final cost.

If you’re interested in joining Olof for a DesignOnDemand™ session visit click here.

You can also rech out to Olof directly at olof.brown@flexqube.com

You may also like: