Here are a few of the most popular solutions we sold over the Summer

This Summer has been quite busy and full on for FlexQube, we have been busy hiring new colleagues, meeting new customers and of course selling some great new solutions. Our design department has been busy creating both complex and simple designs for our customers. We have already designed over 600 individual solutions in 2018 and the year isn’t even over yet!

We thought it was time for a quick update on some of our newest solutions that have been sold, throughout, Europe, Mexico, and the USA. These below solutions have all been designed and then prepared to be shipped out this past Summer:

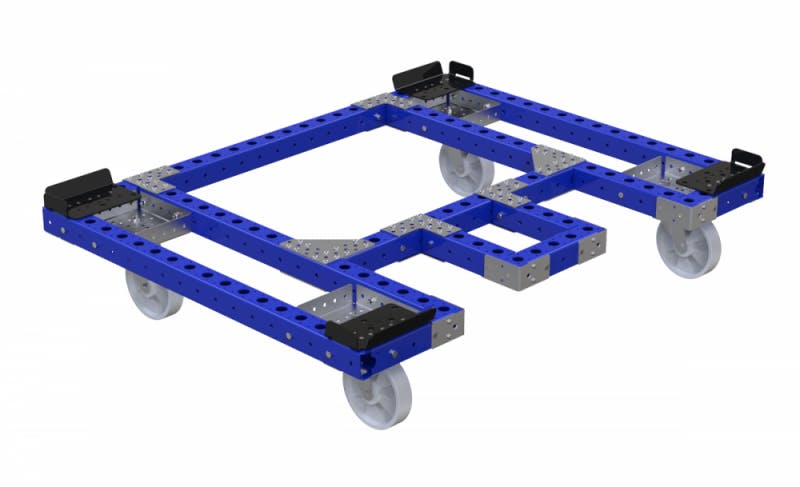

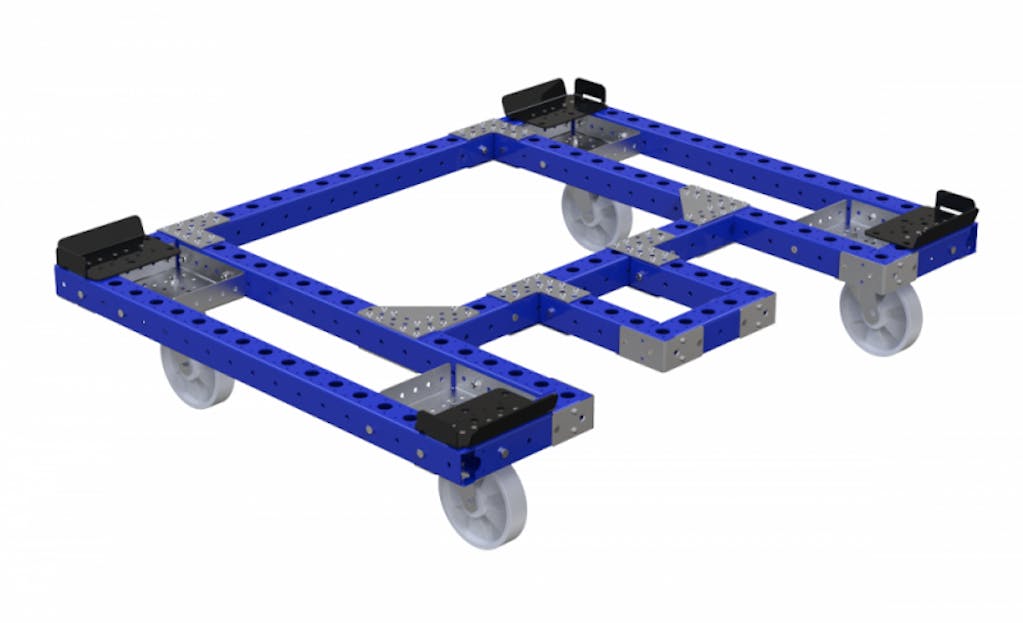

50 x 64 Inch (1610 x 1260 mm) Pallet Cart with Picking Area – Q-100-0940

This pallet cart is quite a simple design but can have a large impact on the picking ergonomics for the operators. The two sections where the cart goes in, allows the picker to more easily access the materials. This cart can be customized, by having a tow bar or handle bar added to the cart.

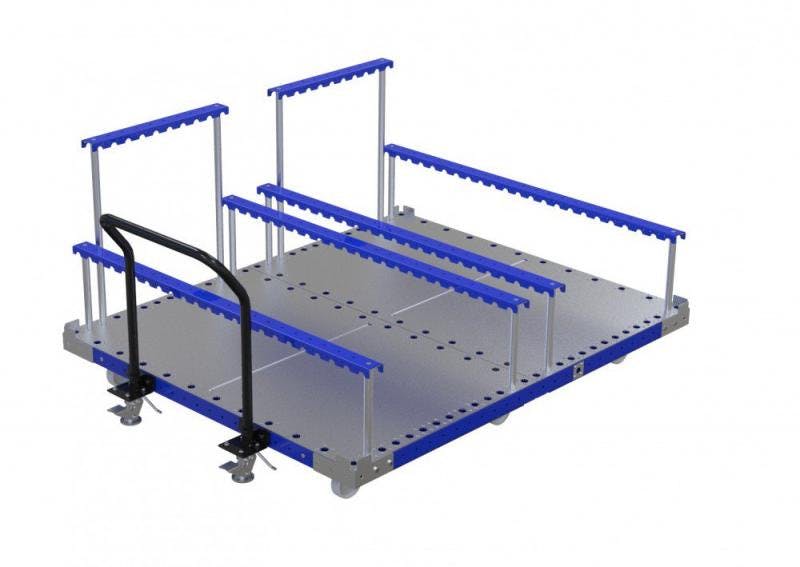

63 x 77 Inch (1960 x 1610 mm) Cart for Seats – Q-100-0652

This cart has been specially designed to help a customer more efficiently move seats throughout the facility. The seats are placed in the 2 aisles of the cart with up to 3 or 4 seats per aisle which greatly increases the carrying capacity when compared to their previous solution. This cart is also equipped with an ergonomic handle bar as well as two floor lock brakes to keep the cart secure in place.

28 x 50 Inch (1260 x 700 mm) Tugger Shelf Cart – Q-100-0754

This is a very simple but very efficient tugger shelf cart design. With all FlexQube shelf carts you can let your materials dictate the height of the shelves because the shelf height can be adjusted within 70mm intervals. It is also very easy to add more or less shelves. This cart is also equipped with a tongue and hitch tow bar so it can be used within a tugger train system.

30 x 33 Inch (770 x 840 mm) Pallet Cart – Q-100-1165

This 30 x 33 inch push cart is a smaller version of some of our pallet carts. This cart is still equipped for taking fully loaded containers, bins, boxes as well as other heavy materials. This cart is designed to fit into the STILL Liftrunner tugger train frames. This cart comes equipped with a floor lock brake and an ergonomic handle bar.

41 x 66 inch (1680 x 1050mm) Kit Cart – Q-100-1185

This kit-cart is a great example of how creative you can get with the FlexQube concept and how the solutions can be customized for your materials. This cart is used to hold up plates or very long and thin materials in place. The materials can be placed in between each of the tubes, this makes it easy to load and unload the materials.

50 x 50 inch (1260 x 1260 mm) Tugger Cart – Q-100-0744

This tugger cart is a very simple design but is a heavy duty and sturdy solution that can hold heavy loads. It is perfectly designed to carry pallets and containers in a tugger train system. It is equipped with a wire release tow bar which vastly improves the ergonomics of the cart for the operator. The operator only needs to pull on the lever underneath the ergonomic handle bar to release the tow bar.

So far this year we have found the need for custom material handling equipment is on the rise. Many companies have been coming to us to have solutions that are specially designed to match their materials, while also keeping flexibility for future materials. The balance with material presentation and material transporation is always a fine line, but with the FlexQUbe concept you can combine these two concepts until you find the perfect balance for your material flow and materials.

If you’re looking for custom material handling equipment, contact us at sales@flexqube.com

You may also like:

How to start the transition from forklifts to a tugger train system