How to Use Flatbed Carts to Improve Your Material Handling

Flatbed carts may seem like simple tools that are used in warehouses, factories, and other places where there is a need to move materials from one point to another.

However, the importance of having this tool in these facilities cannot be overstated. Companies that manufacture, process, receive, and dispose of large amounts of products as part of their regular operations know the value of using the right type of carts when it comes to efficiency and productivity. Most owners of this type of business consider purchasing flatbeds as an investment towards the overall quality of their products and services and this material handling equipment deliver.

What are Flatbed Carts?

Flatbed carts are essentially trolleys with a flatbed top where items can be placed so they can be rolled to a different location. They actually look like rolling tables with handles that allow users to grab and push them smoothly on a flat surface. These flatbed carts can come up to waist-high or sometimes just up to mid-calf in height. This would largely depend on how the carts will be used.

The carts are also equipped with wheels. These swivel wheels make the movement and transportation of the carts easier to accomplish. Flatbed carts are great for handling heavy loads and efficiently moving them across shop floors.

A Convenient Tool for Material Handling

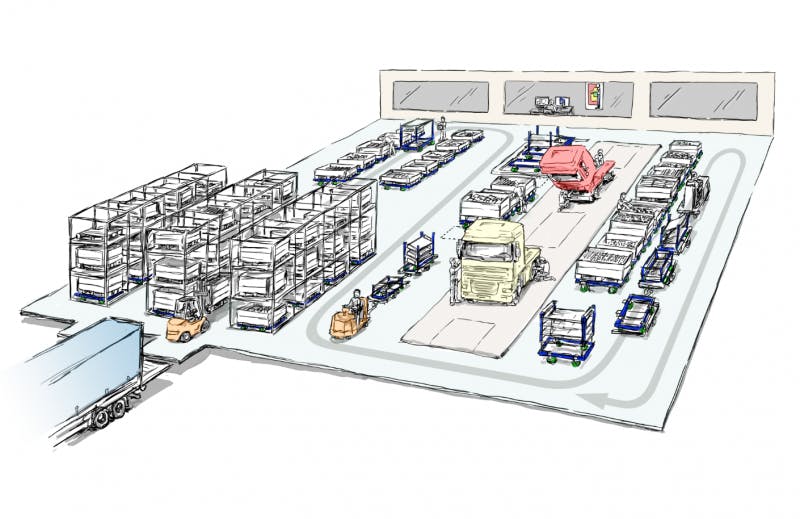

Flatbeds are typically used in the manufacturing industry, usually in factories and warehouses. The most obvious reason for using these carts is the convenience of moving materials and goods from one area to another. However, there’s more to these carts than just convenience. These carts actually give businesses the advantage of being able to reduce material damage. These carts are stable enough to hold properly loaded materials and goods so they do not get banged around too much to cause damage. Consequently, this leads to less wastage and losses in manufacturing and warehousing.

Investing in flatbeds for your material handling requirements, however, is not enough. You need to know how to use this tool properly so it serves its purpose. Follow these tips when using flatbeds:

1. Start by knowing what type of flatbed you need

Not all flatbed carts are the same. There are actually several types today varying in height, handles, wheels, load, and even levels. You’ll find that some carts only have one surface on which to put items. Other forms of flatbed carts may also have shelves that are designed for smaller components and materials, these are also referred to as shelf carts.

Also, consider how you intend to apply the carts in your facilities. Understanding the mode of application simplifies the process of choosing the right cart.

2. Create a pathway

Your flatbed carts will not be as effective if you do not have a flat surface where they can be rolled through smoothly. It’s basically like paving roads in warehouses where you “drive” flatbeds instead of cars. Such pathways should be designed and planned wisely so you can efficiently maneuver the carts around the warehouse. An efficiently designed pathway speeds up delivery times and supports the safe use of flatbeds. They also elongate the lifespan of your cart.

3. Think of spaces, entry ways, and exits

The goal of using flatbeds is to transfer goods with minimal chances of damage or loss. For safer and more secure material handling using these carts, you should ensure that there’s enough space for the loaded carts to move around in the storage area. The flatbeds that you invest in should also be able to conveniently accommodate the load that you intend to put on them. Don’t forget to consider elevators, gates, and even sliding/ automated doors on transportation vehicles. It might be necessary for you to take your goods through these areas. All these details relating to moving the flatbed must be integrated into the floor plan of your facility.

4. Establish a load maximum

You can argue that this should already be indicated on the carts themselves. However, if you really think about it, you will realize that just quoting a number (100 kilos, for instance) might not be a good guide for your employees. You have to make it easy for them to understand what the load limit is. Instead of rattling off figures, you can simply say that each cart can accommodate 20 boxes. Developing a simple system for recognizing load capacity will ensure safe use and increase the lifespan of the flatbed cart.

5. Invest in maintenance

Like other tools and equipment that you use in your business operations, you have to ensure that your flatbeds are properly maintained. Otherwise, they will not be of use at all. What’s worse, what you invested in to keep your goods secure could be the cause of costly damage. Therefore, it is important employees working with flatbed carts understand the proper way to use them. This is why extensive training about material handling is recommended to factory owners.

6. Label your flatbeds

There’s a good chance that you will be using more than one flatbed for your business operations. To help monitor their condition and use, you need to make sure that they are properly labelled with perhaps the area where they are used or the product category they are supposed to carry. In bigger companies, these tools would be labelled with stickers that contain the item name, code, personnel accountable for it, and date of acquisition. Proper labelling ensures that the corresponding flatbed is available when it is needed.

7. Train your handlers

You might think that it is easy enough to use flatbed carts. It’s not always a good thing to assume that anyone assigned for your material handling tasks would be able to manage his cart properly. It is best to take the time to train the handlers on how to use the flatbed. Aside from the basics like identifying the parts of the trolley, how to push and steer the trolley, what is the load requirement, the trainers should be able to observe the handlers on-the-job. It is important to see that they can actually apply what they learned from their training. Effective training has its benefits. These benefits include safety in the workplace, reducing cart wear and tear, and reducing damage to the material.

8. Think of creative ways to maximize the use of your flatbeds

Remember that one of the goals of using flatbeds is to improve the efficiency of your work flow. Do not stop at merely enjoying the convenience that using flatbeds give you. Think of ways on how you can make the loading process faster. Perhaps you can think of changing your usual route so you can get from pick up to drop off faster. Instead of loading boxes piece by piece onto the flatbed, you can perhaps fit everything in a single box and then load that box on your flatbed carts.

Flatbed trolleys can bring a lot of advantages to the material handling side of your business operations.It is important to realize that the benefits it results in extend beyond the warehouse or storage units. Less damage means more goods making it to the stores and the customers. This translates to more revenues too. With such efficiency in the backroom, you can deliver on the promises to your customers or perhaps you can even exceed your customers’ expectations by getting their products to them sooner. Finally, you can choose to customize your flatbed carts if your facility’s needs are unique. FlexQube’s Design on Demand customization process will ensure the end product perfectly meets your requirements.

If you’re looking for a similar solution, contact us at sales@flexqube.com

You may also like:

FlexQube’s top 5 industrial push carts

How to start the transition from forklifts to a tugger train system?