The Basics of AMR Robots

Updated: 2023-10-24

AMR robots have been one of the most discussed forms of automation technology in manufacturing and distribution centers. The potential to have automated transportation is a huge benefit to save on costs but also to fight off labor shortages.

In this article you’ll learn:

- Why should you implement AMR robots in your facility?

- What is an AMR robot?

- The basics of AMR technology

Why should you implement AMR Robots in your facility?

When implementing automation in your facility, you must know what you are trying to accomplish. To accomplish runnign an efficient facility, it’s crucial to ensure your automated material transports are reliable.

If your transportation method changes its path when it detects an obstacle, it can cause errors in your operation. This can also be nerve-racking for employees and operators to know that there can be a sudden change of course when transporting heavy components. Using an AMR that waits for obstacle removal or move around obstacles before continuing is better for your operations. It maintains efficiency and prioritizes safety.

When you start automating, don’t just go with the crowd and ask for a “smart robot”. Instead, find the right solution for your specific needs.

To help understand further what the possibilities are, we will begin by establishing what an AMR is.

What is an AMR Robot?

AMR (Autonomous Mobile Robot) is a robot that moves on its own without tapes or being controlled by operators. AMR robots incorporate advanced navigation technology to map out the environment and determine their route as they move. AMR technology helps make operations safer and more flexible, freeing up operators to focus on tasks other than monitoring material transportation.

The Basics of AMR Technology

The piece of technology that allows the AMR to stand out is its navigation technology. The technology that enables the AMR to navigate is it’s sensors.

AMR Robot Sensors

For the AMRs to navigate so well, they need to have highly advanced sensors installed into their unit. The most common sensors are 3D cameras or LiDAR sensors.

LiDAR scanners is a system that emits laser lights to reach the surrounding surface. The light reflects back to the sensors which registeres the environment. The processing system of the AMR calculates the time it took for the light to reflect back to the sensors. This allows the LIDAR scanners to to map the distance between the AMR and surrounding objects which helps the AMR to determine how to navigate.

3D Cameras is an updated technology for AMR navigation. It measures the pixel distance of two images of the same scene. Additionally, a 3D camera adds an extra measure of precaution by emitting an infrared light pattern. This helps to determine obstacles despite low contrasts, such as a white wall, and locate the distance.

Want to know more? Contact us

How does the AMR Robot know how far it has traveled?

The AMR robot also needs to know how far it has traveled to accure information about its route.

The AMR can estimate how far it has traveled by measuring the amount of time the motors have been driving. It also uses motion sensors to estimate to robot’s position over time.

However, this method can be quite sensitive to errors. To be accurate, the AMR gathers data, regularly calibrate instruments, and process information to limit potential errors during its drive.

How does the AMR Robot know its location?

The AMR needs to understand where it is within the facility to determine where to navigate to next. The AMR robots can only do an estimation of its position by determining whether the laser scanners match the map. People commonly refer to this as scan matching.

There can be a few different ways to perform scan matching such as:

- Iterative Closest Point (ICP)

- Scan to scan

- Scan to map

- Map to map

- Feature-based

By help of scan matching, the robot can estimate it’s location and see if the scans match the map. Then the AMR begins to eliminate the guesses which do not match up with the plan.

In general, AMR robots do this estimation 15 times per second. If an AMR is unable to localize itself and the scans do match, it goes into a mode called mislocalized.

Once the AMR localizes itself within the facilty, it needs to then locate the object. Most AMRs use laser scanners to detect a significant shape that it is programmed to detect.

How does an AMR Robot set up a Map?

The way that an AMR can map its surroundings is by a method called SLAM (simultaneous localization and mapping). Some methods of doing this are:

- Extended Kalman Filter

- Covariance Intersection

- Particle Filter

- GraphSLAM

FlexQube AMR Robots

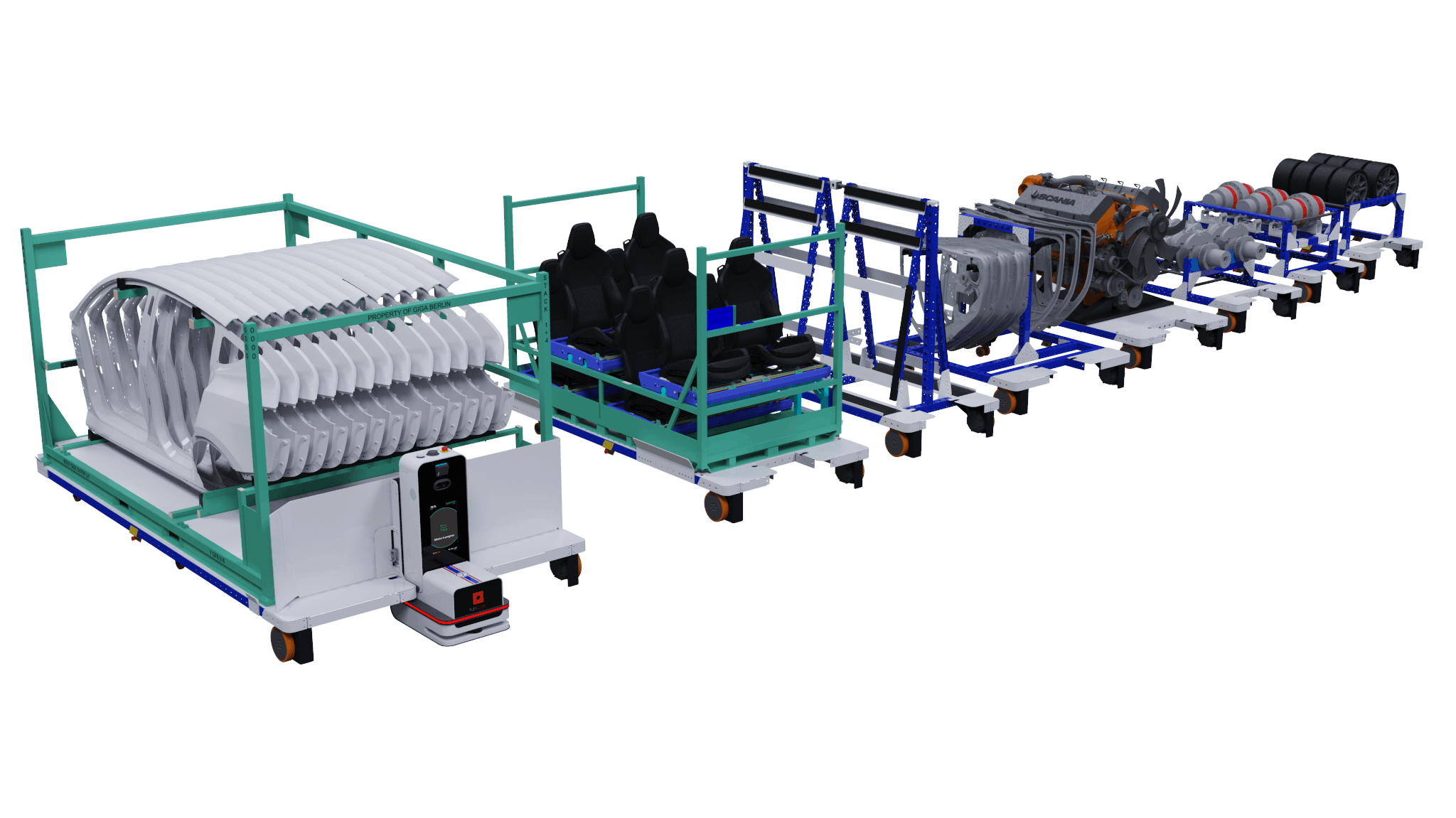

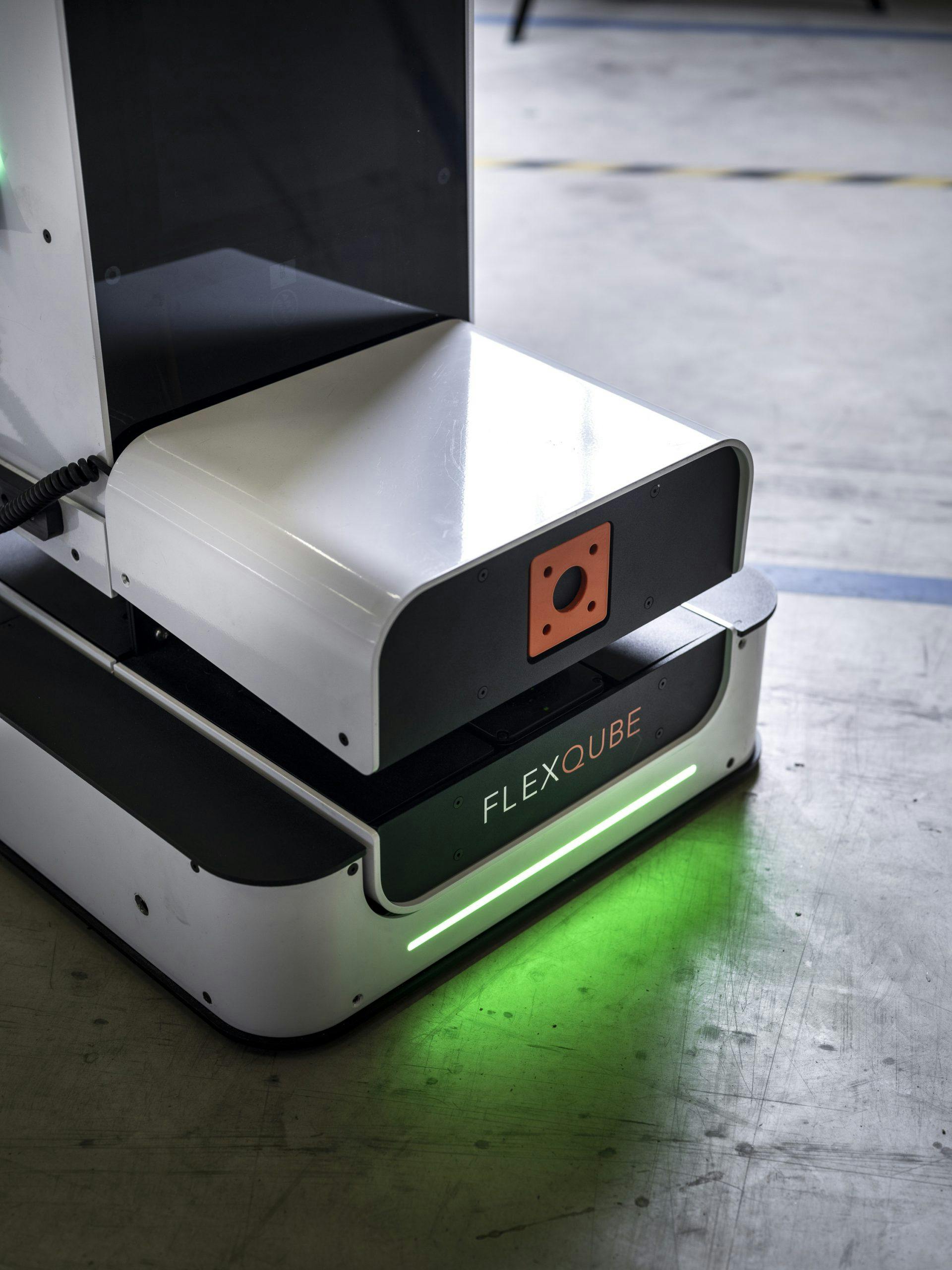

No one can deny that implementing an AMR robot for the right purpose brings many benefits. The use case and how to use the technology determine everything. At FlexQube, we have implemented our own automation solution, the FlexQube AMR Robot.

The FlexQube AMR Robot is a modular “one robot/multi-carrier” concept that delivers on the promise of robotics for material transportation. The standardized interface is created to be adapted for your factory’s varying needs. Based on the evolution of our carrier-based expertise and experience, it couples everything we’ve learned with technology partnerships to give modern manufacturing the transformation it’s been waiting for: robotics that delivers.