The benefits of a tongue and hitch based tugger train system

Choosing between a tongue and hitch tugger train system and a mother-daughter type can be tricky. Below we try to bring up some pros and cons with both concepts. FlexQube can supply carts and dollies that would work with both a tongue and hitch setup, as well as with different mother-daughter cart concepts.

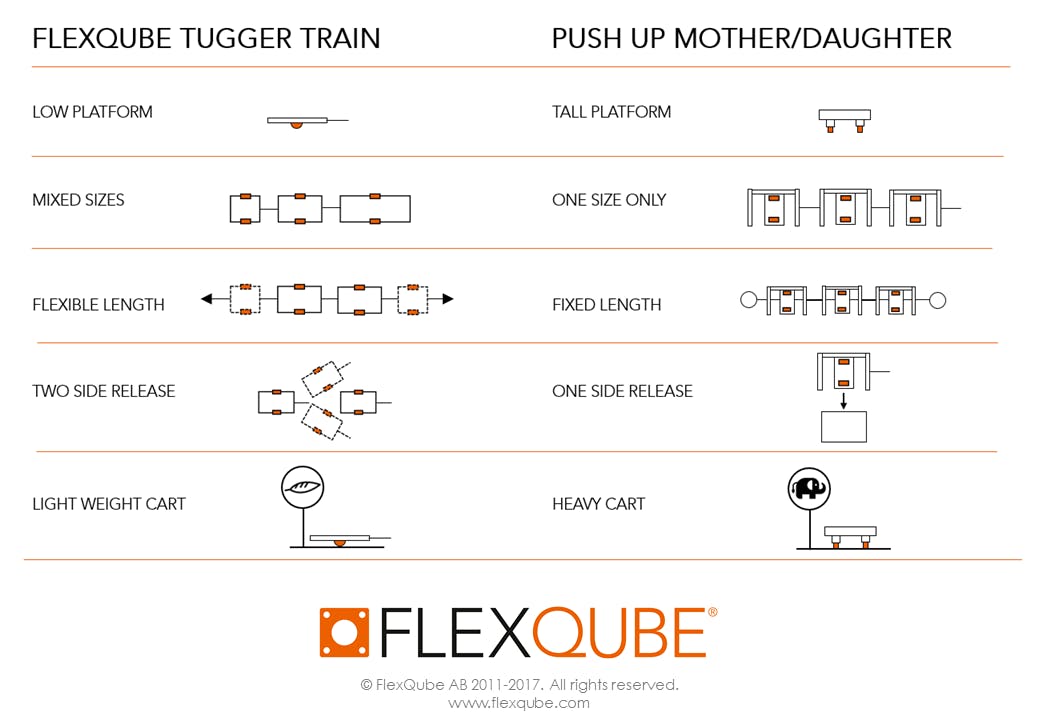

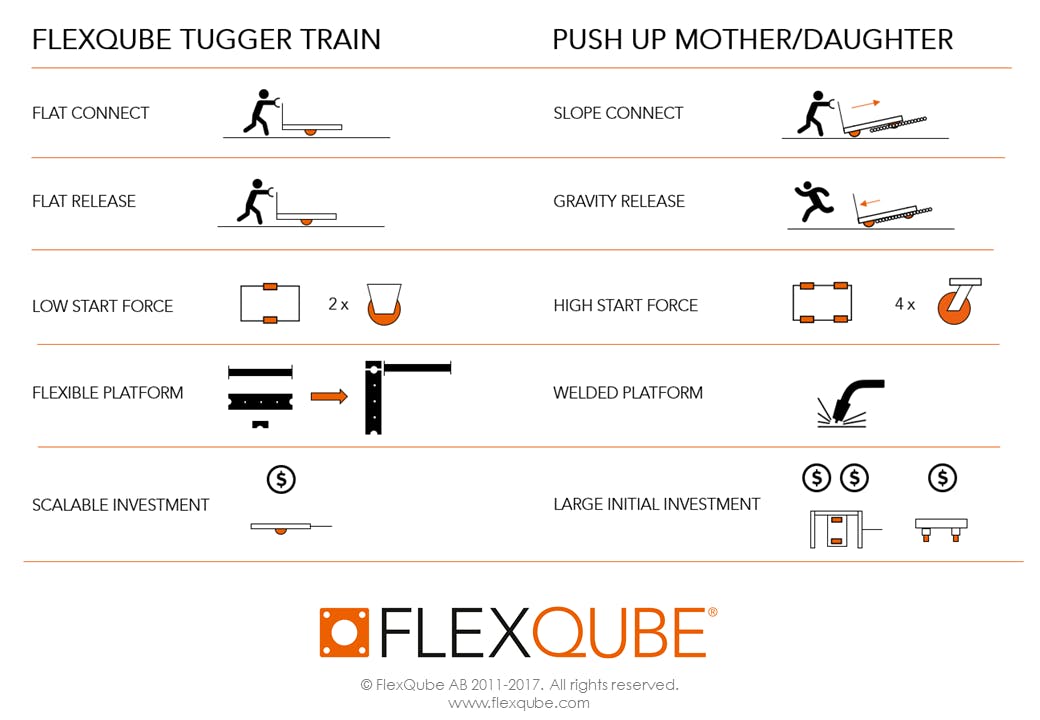

If you connect the carts together with a tow bar it is possible to create what we at FlexQube refer to as a ‘low rider’; a cart that has a very low loading height (short distance from floor to the loading deck). That makes it possible to stack taller loads (bring more material at the same time and hence gain in productivity) on the cart and still have the material presented in an ergonomic height for the operators. With great quality and proven heavy duty 5 inch (125 mm) polyurethane casters that are integrated into the cart base, the steel deck will sit just about 5.5 inch (135 mm) off the ground. With the high quality casters, the carts run silently around the plant and works perfect on many floors, even floors in worse conditions.

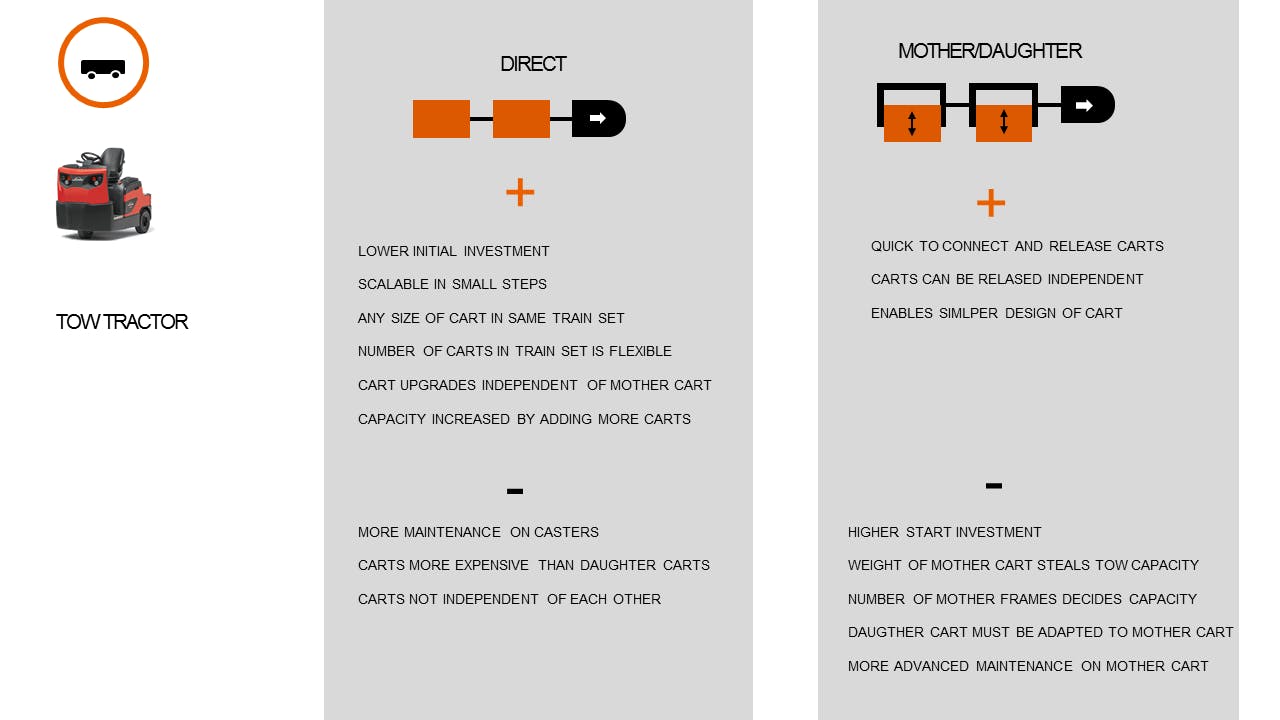

Since there is no frame that limits the size of the dollies, as in a tugger system based on separate frames, the possibility to mix and match carts in different sizes in the train is unlimited. That allows great flexibility to bring different sized containers and types of carts; kit-carts, pallet carts or shelf carts, in the same train set, mixed differently on each route.

By being independent of the frames the number of carts in each tugger train is also adjustable/flexible. Run 1,2,3,4,5,6,7,8 carts (or more depending on your fork lift aislle width) in the same train and connect and disconnect as you wish since there are no frames setting the limit for the number of carts at the same time. Just as well, there will be no empty slots in the train if you only need to run two carts but have four frames, where two will be empty if you use the mother-daughter type concept.

Most of the mother-daughter frame systems today only allow release on one side of the frame. One exception to this is the B-frame sold by STILL GmbH that FlexQube has an official partnership with. This means that the routes have to be planned in such a way that the frames are set to open to the side where the material is needed. Since there is a need for a handlebar, most of the times to allow an ergonomic handling of the dollies for the operator, the dollies need to be rotated 180 degrees when taken off the train and placed at the work station. That kind of movement is one of the worst from an ergonomic standpoint for the human body and something that HSE officers often complain about.

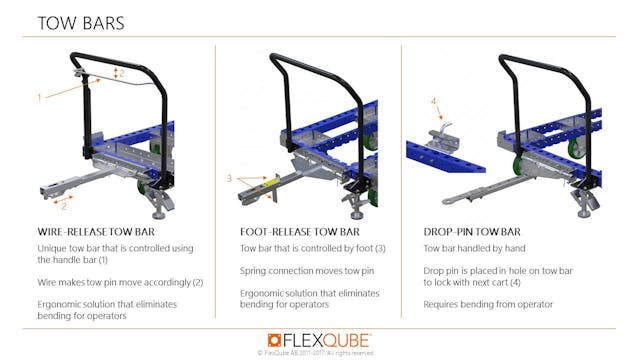

Using a tongue and hitch system with fixed casters placed in the center of the cart allows release from the train to both sides of the aisle. It is also much easier to turn the cart to its intended position at the line since it is only needed to turn 90 degrees. And anyone who have tried to move a cart with four swivel casters compared to a cart with fixed casters in the center of the cart and swivel in the short ends, knows how much easier this is.

A natural benefit that is always included in the FlexQube concept are more light weight carts compared to welded carts. As a matter of fact, in a direct comparison between FlexQube and competing cart suppliers on the US market, one of our customers found the FlexQube cart to be 40% lighter. And this cart holds 2000 lbs. and the customer has been using 100 of these carts for 3 years now.

Another important aspect concerning the release of the carts is the angled ramp or slope that some tugger train suppliers use. The ramp has a slight incline allowing the daughter cart to be connected to the mother cart without having the casters of the daughter cart touching the ground during transport. This means that heavy carts have to be pushed up a ramp, against gravity, something that can be hard for people. The greater risk though, lies in the fact that upon release of the daughter cart from the mother frame, the daughter carts slides off the ramp in a motion that could cause injuries if the operator trips and have the cart hitting him or her. This specific risk has also been something that some of our clients identified causing this kind of push up mother daughter cart system to be forbidden in the plant, just from a safety perspective.

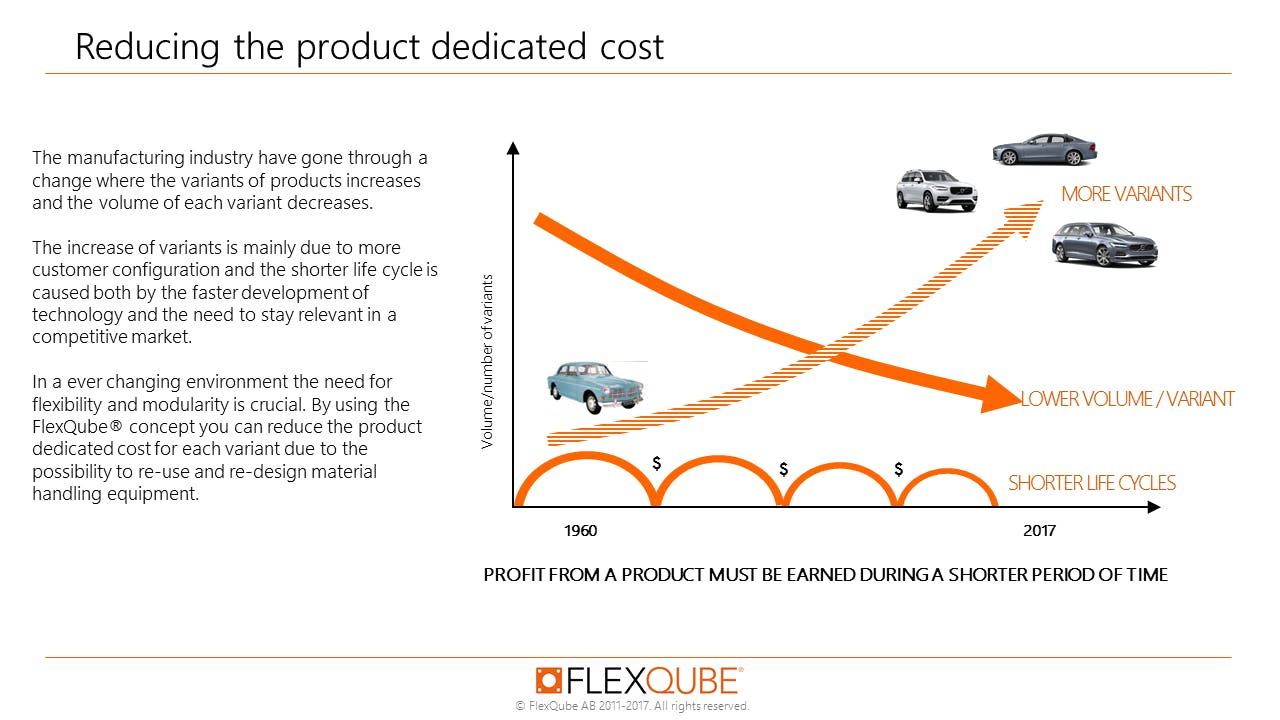

Heraclitus, who lived about 500 BC, already then realized one important thing that is the core of the FlexQube concept; ‘Change is the only constant’. Even 2500 years back Heraclitus got it right, nothing will stay the same forever, it all changes. And nowadays that is more true than ever.

Volumes change, mix change, product change. More and more often.

FlexQube believes that making welded carts in this market environment is a bad idea. Using a fixed mother cart frame system in an environment where mix is high and products and things change rapidly could be a bad idea as well. But keeping a standard frame set could also be something that limits the variation and sets the boundaries for the logistics system. But, in that case, make sure to have the flexibility built in to your carts instead.

Swith to FlexQube – Switch to a future proof concept!

Anders Fogelberg

CEO the FlexQube Group

If you’re looking for a similar solution, contact us at sales@flexqube.com

You may also like:

FlexQube’s top 5 industrial push carts

The importance of custom material handling carts

How to start the transition from forklifts to a tugger train system