The best of flat deck tugger carts by FlexQube

Flat deck tugger carts for containers and pallets are the most common application, when transferring from a fork lift driven supply of material to assembly and production lines, to tugger train routes with several carts connected in a train. Every year almost 100 employees are killed in fork lift related accidents. Keep them safe by switching to the FlexQube fork-lift free initiative.

Below we have gathered our most common and best-selling versions of transportation carts with or without steel deck for many different sized standard containers; like 48″ containers or gaylord containers, 48 by 40 inch containers or EUR pallets in size 1200 x 800 mm. FlexQube also integrates with mother daughter solutions, e.g. the Liftrunner system by STILL.

1. Flat deck industrial tugger cart 50 x 50 inch for 48 by 48 inch or 48 by 40 inch containers or smaller.

This cart carries up to 2000 lbs. and is equipped with a foot release tow bar, handle bar with floor lock brake and six heavy duty 200 mm (8 inch) polyurethane casters where the fixed casters are in the center of the cart to achieve best tracking behind the tugger.

This cart is also available with drop pin hitch, find it here. Customer references for this cart is found at many locations in e.g. Canada, USA, Mexico. sales@flexqube.comfor more information! Watch a video from a customer who use more than 125 carts of this type.

If you’re looking for a similar solution, contact us at sales@flexqube.com

2. EUR pallet cart or trolley for 1200 x 800 mm pallets or Volvo pallets (1225 x 820 mm) with handle bar and wire release tow bar.

This cart carries up to 1200 lbs./550 kg and it has four casters in a diamond setup where fixed casters are positioned in the center of the cart and one swivel caster (crazy wheel as some call them) in each short end of the cart. The EUR pallet trolley has a floor lock brake.

What’s unique about this tugger train cart is the release and coupling function of the hitch where it can be disconnected by pulling a lever on the handle bar (the trigger handle). By doing so the tow bar is disconnected from the cart in front of it without having the operator bend down to release it. This has a positive effect on both the ergonomics for the operator but also the time it takes to connect and disconnect carts.

Watch a video of this application in use at a customer who have more than 800 carts of this type in use.

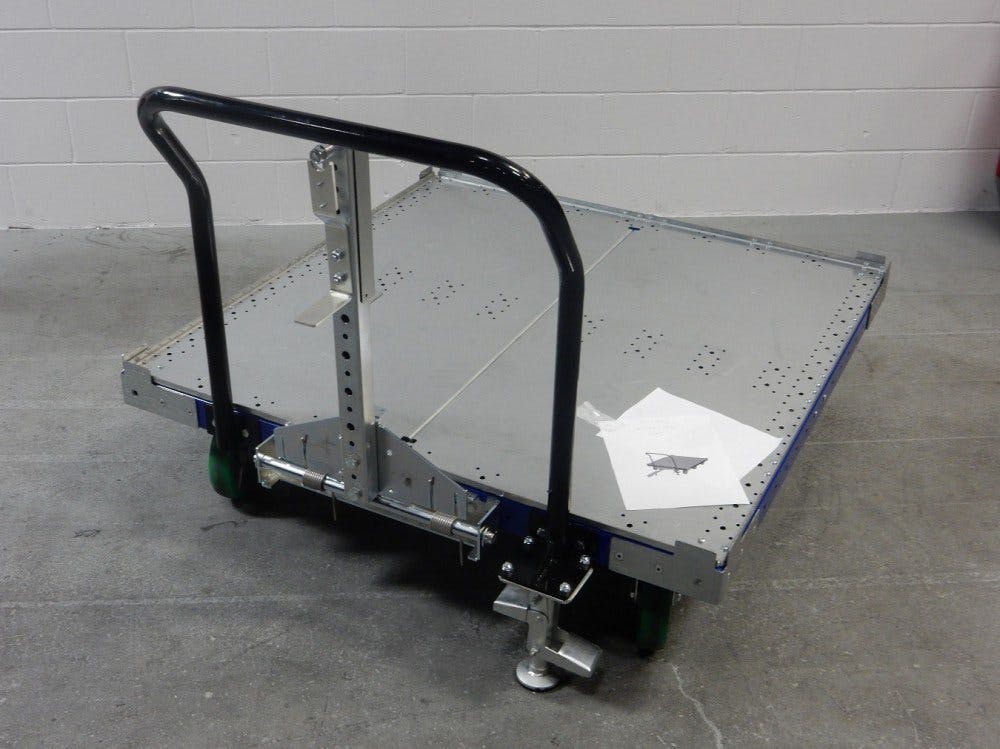

3. 48 x 40 inch steel deck cart with removable handle bar, tow bar, and floor lock brake.

This container cart for tugger train applications in a size that is perfect for 48 inch x 40 inch standard containers, has a removable handle bar.

4. Low rider flat deck cart for containers with smaller casters and integrated platform to achieve lowest possible height of cart.

This cart is equipped with six 125 mm (5 inch) casters integrated in the steel deck platform in order to keep the container as close to the floor as possible. The lip on the tow bar is modular which makes it possible to adjust the size of the hole for the type of tugger you are using. The hitch is a drop pin type, spring loaded, for convenient coupling and decoupling of carts. The cart is rated at 1000 lbs./450 kg capacity and Draexlmaier in South Carolina, USA have almost 200 units of this cart in use.

5. Tugger cart for containers without steel deck.

Frame built by FlexQube standard components and six caster setup for optimal tracking in tugger train. Optimal for container sizes 48 by 45 inches. Possible to add a steel deck to the cart. Autoliv in Mexico has a lot of these carts in use.

In our Solutions Library™ you will find all of our tugger carts in different sizes and shapes.

You may also like:

FlexQube’s top 5 industrial push carts