How to Improve Order Picking In Your Warehouse

Last Modified: 30.08.2022

To maintain a median picking accuracy rate of manual order picking going above 99%, you need increasingly faster, more efficient warehouse automation approaches.

In this blog post, we will:

- discuss what is order picking and explain different picking methods

- analyze how to choose the correct order picking method

- list the various approaches and technologies involved in it and point out the main differences between manual and automated order picking

- provide actionable steps to optimize the order picking process in your organization

Let’s dive right in.

What is order picking?

Order picking refers to the process of pulling an item off the inventory shelf in the warehouse to fulfill a customer’s request.

If we are talking about manual order picking, this is a labor-intensive task that involves collecting the appropriate product and transporting it across the warehouse floor to the packing/delivery zone.

The process of order picking is integral to any business that deals with products stored in warehouses awaiting customer orders. It is a vital part of e-commerce, manufacturing, hospitality, and of course, traditional wholesale and retail industries.

From the definition, it is also easy to note the important role order picking plays in consumer satisfaction. The more efficient a facility’s order picking process is, the quicker a customer gets their order.

According to a survey by Saddle Creek Logistics, order processing speed and accuracy is a key priority for modern e-commerce companies and wholesalers/distributors, with 32% reporting it as one of their top three fulfillment challenges – alongside transportation costs and scalability.

In order picking – every second counts

Picking/packing/shipping is the main reason why companies use third-party logistics (3PL), accounting for 59% of 3PL clients. It is also a significant drain on resources, often accounting for 55% of all warehousing costs.

Of the trio, order picking is probably the most critical process due to its massive time and energy requirements. In the larger warehouses, like Amazon’s, pickers often spend 50% of their time traversing the maze, covering anywhere from 10 to 20 miles in a day.

According to Invesp, recent trends in customer expectations provide sample proof that faster product turnover and satisfied customer is relevant for bigger and smaller warehouse facilities, since:

- 61% of customers are willing to pay more for same-day delivery

- 65% of retailers have plans to offer same-day delivery within 2 years

- 49% of consumers say that same-day delivery will make them more likely to shop online

Naturally, any improvements in speed and accuracy in the order picking process could have a massive impact on your business productivity. Saving just four seconds per pick could result in net productivity boosts of up to 12.5%.

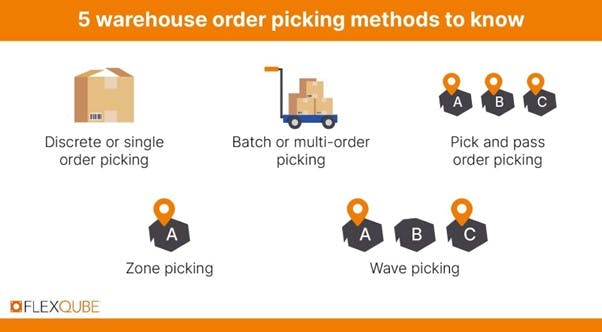

5 warehouse order picking methods to know

Order picking is a complex process with several stages like setup, travel, search, and finally pick-up. Over time, specialists have developed several picking methods, each with its set of strengths and weaknesses.

1. Zone picking

The zonal method of picking orders focuses on creating dedicated picking zones for shop floor workers to pick items from. In this technique, several zones are created within the warehouse or shop floor that may serve as both storage and order picking zones.

The store-keeping unit of products (SKU) stored within zones must be accurate. With items spread across multiple zones, fulfilling a single order may require multiple pickers. A paperless management system with tracking and scanning systems is absolutely vital for efficiency and coordination here.

The process of picking orders from specified zones can be made easier using the right technology. The use of digital pick lists and an automated picking process ensures errors are reduced.

Zone picking is generally employed by a larger business that stores a wide array of different SKUs – this includes supermarkets and OEM manufacturers who produce items consisting of assembled components.

The zonal system is also highly compatible with automated guided vehicles. With everything neatly arranged into zones, programming the vehicles to perform delivery runs from different zones to a central order assimilation area is easier.

2. Discrete or single order picking

The discrete picking method is the oldest technique deployed on shop floors. It involves pickers with pick lists going through the inventory to find selected items needed to fulfill an order.

As expected, this is the most inefficient method: the picker may have to tour the entire facility to find individual items, even with an SKU system in place.

Thus, it is generally used in small warehouses or shop floors with a limited number of items. Alternatively, discrete picking is employed in large warehouses where heavy-duty equipment or items are required to fulfill an order.

Discrete picking relies on manual carts such as shelf carts to aid the picker. While upgrades to fully automated carts and vehicles may not be practical in smaller warehouses, other nominal automation upgrades can improve things considerably.

Digital inventory management systems, tracking with barcodes, and guidance systems involving the pick to light or pick to voice are all easy to integrate into existing warehouse systems.

For example, with a simple pick-to-voice system, a picker can save countless minutes wasted on checking papers, layouts, or any other visual cues for guidance to their destination within the warehouse.

3. Batch or multi-order picking

The batch picking process involves the picking of multiple orders at a time to speed up the entire process. In this scenario, a picker is given a pick list consisting of items in an order fulfillment batch and he or she is allowed to pick all the items at the same time.

The batch picking technique is designed for large warehouses with different storage areas across the shop floor.

Thus, the picker visits all these storage centers and picks all the items needed for a particular order. This process is generally used to pick small items and it can be significantly improved by shifting to an automated parts-to-picker system.

The main problem with batch picking is the time spent picking items from different zones. Instead, the warehouse could implement automated systems with robotic arms to pick products, delivering them to a central location using carousel systems.

4. Pick and pass order picking

This method can be viewed as a subset of the zone picking method although some important differences exist. During pick and pass, a worker picks all the SKUs required from a particular zone in the warehouse before moving to another zone.

Its application involves picking all the items available in Zone A, before moving to zone B and other zones. Thus, items are picked by zone until they get to where they are processed for delivery or assembly.

Automated delivery vehicles are a great upgrade from pick and pass systems. Since this approach involves the accumulation of loads from different zones, the payloads tend to be higher than other approaches.

It could put more strain on the picker, especially as they cover longer distances across multiple zones. Self-driving vehicles can remove this stress completely, reducing the toll on the pickers’ energy levels. Voice-guided systems can also help cut down travel and search times.

5. Wave order picking

This method involves a single picker preparing an order according to the fulfillment timeline attributed to the order. Thus, orders are prioritized and the picker picks all the items across every zone required to fulfill an order.

The wave technique can also be applied when multiple orders of a similar product must be fulfilled. In this situation, the picker prioritizes a batch of similar orders and picks the items needed to fulfill them.

When multiple orders are being processed simultaneously, pickers often end up with heavy loads of items. Even smaller retail SKUs can add up quickly and create a heavy burden when you are processing multiple batches.

Wave picking could be improved significantly with a shift to an automated parts-to-picker approach in larger warehouses. Instead of traversing across multiple zones, the picker could stay in a central section and receive parts on priority from different zones via carousel systems.

How to choose the correct order picking method

Each of the order picking methods mentioned above has its advantages and disadvantages. Choosing the appropriate method will depend on several factors:

- Your company’s operation type

- Specifications of the products

- Number of orders and transactions handled

- Number of picks on a given order

- Number of picks from a given SKU

- The use of case pick, piece pick, and full-pallet loading

Depending on these factors, you may need to employ a combination of the available order picking methods and embrace some level of automation technology.

Order picking is an essential part of your business, and its importance only grows as you get more customers. You need to improve on efficiency and accuracy while reducing picking times.

You need to choose the correct picking methods as well as follow the best order picking practices.

When selecting one of the above-mentioned order picking methods, you will need to make sure some key factors are taken care of. Some of the factors that you will need to think about are:

- Your inventory is consistently stocked.

- The routes you choose to pick on are optimized.

- Begin investing in smart automation (such as FlexQube’s eQart)

- Make sure you have the data of all of your errors.

Keeping track of the factors above will make the order picking method you choose much easier to manage and much more efficient for your warehouse.

Manual vs automated order picking

Despite the constant technological advances in warehousing and logistics, order picking is still dominated by manual picking. Even Amazon, which invests billions into robotics, doesn’t expect robots to replace its warehouse workers any time in the next decade.

However, this is not necessarily a black-and-white choice between fully manual and fully automated processes. Successful attempts to improve operational efficiency in order picking involve combining manual labor with some degree of automation.

One thing is beyond doubt – traditional, paper-based, manual order picking systems are woefully inadequate for the demands of the modern market.

There are two main approaches to automation in order picking:

Parts-to-picker – this involves using automated solutions to bring the product to the picker. Some popular options include automated storage and retrieval systems, vertical lift modules, and automated carousel-based storage systems.

Picker-to-parts – this involves paperless picking/inventory management systems, automated guided vehicles, pickup robots, and other solutions that help pickers reach the product faster and with more accuracy.

These approaches represent varying levels of automation within the order picking process. Based on the level of automation, we can identify four sequential levels:

- Manual Picking – this is the slowest and the least efficient approach where all aspects of picking – from setup to travel, search, and the final pick – are performed by the order picker. The risk of picking the wrong product is very high in this model. It also comes with the highest risk of health effects, accidents, and injuries to the pickers.

- Paperless Picking – a simple yet significant upgrade on manual picking, this involves the use of handheld RFID scanners, pick to voice (PTV), pick to light (PTL), and other wearable augmentations to help improve the accuracy and speed of pickers. But they still have to travel manually to the item location.

- Assisted Picking – using guided transport vehicles and robots, pickers can reduce the time wasted on traveling. Recent systems come with the option of automated return to depots, saving the pickers the time spent on to-and-fro journeys. These systems are also ideal for large and bulky packages.

- Robot Pickers – representing the extreme stage of automation in order picking, this approach involves using fully automated robots that generate order lists, locate the products, set up an optimal sequence, and pick up and drop the items without human assistance. The technology is still evolving and robots are not yet ready to fully replace humans in order picking.

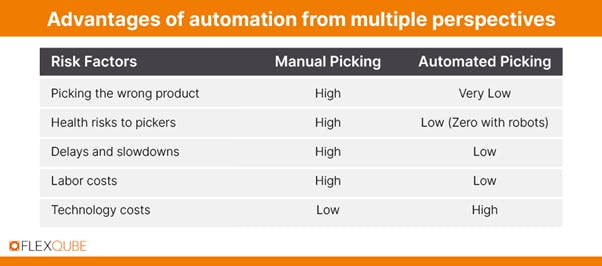

While the journey from fully manual to automated picking is an ongoing process, there are some clear advantages of automation from multiple perspectives. This table outlines the more important factors:

General tips for optimizing part & order picking

Place the popular items nearest

If half of the orders you get come from 10% of the products you have in the inventory, place these items nearest to the entrance of the picking area. Sort according to popularity, putting the least popular items at the back. This will improve the speed at which orders are picked.

Use LED screens

In terms of part picking, the use of batch sheets and signposts to direct the picking process isn’t optimal. Using methods such as these can lead to mixed-up orders when there aren’t enough batch sheets, as well as an increased transportation duration when moving materials due to not enough signage.

To eliminate any confusion, the use of LED display screens that beam order requests or a visual system is the way of the 21st century. There is a significant initial investment to implement this, especially within more extensive facilities, but the amount of waste removed far makes up for the investment.

These LED screens can be attached to storage shelves with information about the orders to be picked. When integrated on shop floors, this tip can reduce errors by 40% while increasing the training timeline for new workers by two days.

Pick diverse items with versatile carts

The details and importance of this tip are in the heading. When tasked with picking multiple items or materials for use on the shop floor, having custom material handling equipment is encouraged.

In particular, material handling carts that are designed for your materials are ideal. These specialized carts can be designed to support hanging materials, tools, and other heavy-duty items.

An example of a versatile cart is the Kit Cart Q-100-0843. This cart can be used to transport both tools and other materials throughout the facility.

This reduces the possibility of accidents occurring because it reduces the number of trips needed to transport the materials. It also makes just-in-time delivery possible.

Check and replenish your inventory as needed

There’s nothing more frustrating for a picker than finding an empty slot where the customer’s order is to be picked from.

There are computer applications available that can help you check the status of your inventory. This helps you to order more stock before your inventory becomes depleted.

Tag items using a barcode

Cut one step from the verification process by tagging each item in your inventory with a barcode. This takes out the factor of human error.

Reduce checking the time by improving accuracy

An item will go through a few hands from the time it’s ordered until it goes out of the warehouse. The picking process should be accurate enough so that repacking, and extra quality checks are not needed. Less human intervention means faster processing and less error.

Group similar items together

Slotting, or grouping similar items together can help in reducing product damage or accidents, decreasing congestion, and improving pick times. You may need to review your storage strategies regularly so they are aligned with order demands.

Implement AGVs

Gone are the days of manual inventory and picking. To keep up with the competition, you must employ any technology you can get your hands on to improve the picking process. AGV carts are often used to transport heavy components within different facilities. There are different types of AGVs, but the overall goal is to maintain safer and more efficient material handling in a facility.

Check routing practices

The warehouse layout can have a positive or negative effect on routing practices, depending on how it is arranged. There may be items that are usually ordered together or of the same category, order size, or business type.

Automation is the future of warehouses

We are in the age of the 4th industrial revolution and with it comes automation and the smart factory. Integrating an automated part picking and order picking system will increase the speed of delivery and eliminate inventory errors.

The areas of focus should be on automating the process of ordering items – as well as using automated material handling systems – and the delivery process.

The FlexQube eQart is an ideal solution for performing A to B transports within your facility. It has a concise set-up time and doesn’t need any added infrastructure. This makes it the most cost-efficient automation solution for simple transport. Also, the eQart is a user-friendly and simple AGV which is can be implemented in just a couple of hours.

Taking on the challenge of optimizing the part and order picking process comes with its rewards. These rewards include:

- a more efficient facility

- reduced downtime

- reduced inventory shrinkage

- enhanced order picking accuracy

- reduced possibility of shop floor accidents

- reduced picker workload.

Browse our collection of material handling carts which are ideal for creating a more dynamic part picking process. You can contact us today to learn more about how FlexQube can help you optimize your facility’s part picking system.