What are the differences between the FlexQube AGV System and another AGV?

Choosing the transportation method for moving your materials throughout your facility can be overwhelming.

Improving the delivery of materials from the warehouse to the assembly line, improving the speed of order picking, and more significant presentation of the parts can all be impacted by choice of transportation. With technology continually improving and getting cheaper and cheaper, it makes it difficult for decision-makers to make a final decision on the transportation method. Automation stands out as the future of internal material transportation, and choosing the right technology is vital.

FlexQube has added to our existing modular concept by integrating smart modules to the concept and creating the AGV. In this previous article, we highlighted the differences between the AGV and the AMRs (Autonomous Mobile Robots), but below, we will highlight the differences between the FlexQube AGV and other AGVs (Automated Guided Vehicles).

What is an Automated Guided Vehicle?

MHI.org defines an Automated Guided Vehicle or AGV for short as:

“An automatic guided vehicle system (AGVS) consists of one or more computer-controlled, wheel-based load carriers (normally battery powered) that run on the plant or warehouse floor (or if outdoors on a paved area) without the need for an onboard operator or driver.”

Put simply, an AGV is a driverless transportation system that follows either lines or wires in the floor and is most commonly found within factories, warehouses, or used in other industrial applications. Depending on the system, you choose the levels of complexity can vary. Some basic requirements for a system to be considered an AGV are:

- Self-Driving

- Collision Warnings

- Navigation

What is the FlexQube AGV System?

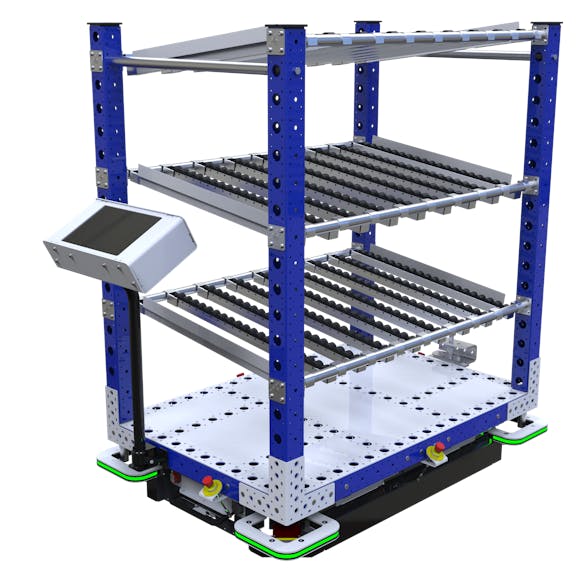

The AGV System is an autonomous and remote-controlled material handling cart. It is designed to carry its load and integrates seamlessly within the existing flexible FlexQube system. The modular system has been complemented with smart modules such as a motor, battery, control unit, and sensors. This allows the AGV to be constructed in a market-leading size range, beginning at 910 x 840 mm up to 2510 x 2510 mm. The AGV can manage to transport load in three different ways, stand-alone load (taking cargo itself), towing material handling carts that have weight, and in an automated mother-daughter configuration.

So what are the key differences between the FlexQube AGV System and other AGVs?

Implementation Time

AGVs tend to have a longer implementation time depending on the form of navigation technology the particular system is using. Many AGVs navigate via magnetic strips, which are installed in the floor of manufacturing facilities. Because of this installation, the implementation time can be long and costly. However, the AGV, which is navigated, optically only needs contrast in the colors on the floor to navigate. This can be set up within 30 minutes of unboxing the AGV using colored tape. This removes the idea that implementing automated solutions takes weeks and instead only a matter of minutes.

Load Bearing

Many AGV solutions do not take load themselves and instead rely on driving underneath a material handling cart is load-bearing and pushing the cart with the load. This means that there is an added cost in having material handling carts that can integrate with that particular AGV system. If the AGV is not driving underneath a material handling cart, it is the most commonly towing material handling carts behind it. While the AGV is also able to pull material handling carts behind up to a weight of 2500kgs, it can also take the direct load. In fact, the AGV can tow up to 2500kgs while still carrying a load of 500kg itself. When not towing any cargo behind, the AGV has a maximum load capacity of 1000kg. This adds a lot more flexibility to how you plan on transporting your materials within your facility. It also removes the added need to have to purchase custom material handling carts to match up with your AGV.

Flexibility

The AGV comes with a market-leading size advantage. The ability to create an automation solution ranging in size from 910 x 840 mm up to 2510 x 2510 mm provides a lot of freedom and flexibility. It isn’t just the size flexibility but also the flexibility to change top structures with ease. The AGV can have a flat deck for transporting pallets but then have a shelf structure added within minutes so it can carry bins and boxes. At the same time, AGV flexibility is entirely based on the material handling carts they are towing behind them. Generally, this locks the user into using inflexible material transport measures.

Simplicity

The AGV System focus has been to create an automation solution that is easy to use and simple for the operators to use. The idea was to make sure that it is simple to use, straightforward to implement, and simple to change if needed. While AGVs may be simpler than some AMRs (autonomous mobile robot) to implement, they can also be challenging to change the routes. Especially if the navigation technology is through magnetic strips in the floor, it can be a very time-consuming process to edit the path. Even when using laser-guided navigation, it can be challenging to alter the route with consultants needed to come in and change the path through software included in the AGV.

When comparing the the FlexQube AGV to other AGVs, it becomes evident that if you are looking for a flexible system to handle a variety of materials, then the FlexQube AGV stands out. But, if you have a designated route with designated products and material handling carts already designed to fit, then maybe the AGV can fulfill your needs. It all comes down to how the automation solution will be used and what is the best fit for your material flow.

CASE / DANA

DANA are ready to meet future challenges with the eQart.

DANA in Mexico was facing a numerous challenges with their internal logistics. They had realized that they needed to boost their efficiency to meet their growing demands. Therefore, DANA saw the potential of the FlexQube concept and making some of their processes automated with our AGV System.