Carts

Tugger Carts

Tugger carts are material handling carts that are towed by a fork truck or tugger but also can be manually transported by an operator.

What is a Tugger Cart?

Tugger carts are material-handling carts that have the option of both being towed by a forklift truck or tugger but also can be manually transported by an operator. The bulk of the time tugger carts are towed within what is commonly referred to as a “tugger train“. These are used within a set-out track, lane or route within a plant or facility to easily transport materials to different work stations. These are most commonly seen within facilities which embrace lean manufacturing or kanban systems for material handling and transportation.

Tugger Cart in Focus

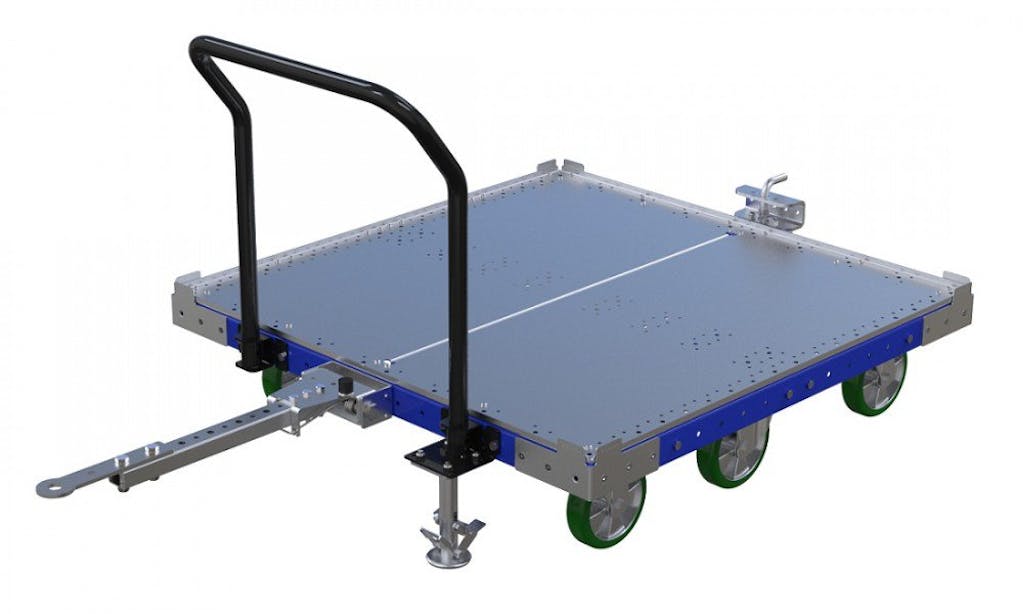

1260 x 1260 mm Q-100-0112

1260 x 1260 mm tugger cart with flat deck for containers sized 48 x 40 inches or 48 x 48 inches. This industrial tugger train cart is equipped with a drop pin tow bar and removable handlebar developed by FlexQube. The cart is designed with a floor brake.

Why buy tugger carts from FlexQube®?

The FlexQube tugger carts are designed to match the dynamic and constantly changing environment material handling currently exists in. Materials are constantly changing which makes it difficult for purchasers and lean engineers to manage their fleet of material handling equipment. The FlexQube concept lets you purchase tugger carts now, but they can then be easily altered in the future.

Tugger carts are a pull-behind cart equipped with tongue and hitch and are a very common type of cart from FlexQube. We offer a wide range of different industrial carts that are robust and flexible and not welded together. This enables your tugger carts to be adjustable and adaptable to future needs. With the FlexQube system, the different carts can be connected to each other and form a tugger train for efficient and safe material handling operations. Some of the most common variants of this are the flat deck tugger carts with handlebars. The handlebar is removable and is placed at an ergonomic height for the operator.

FlexQube offers industrial tugger carts for use in delivering material from your warehouse to your production areas.

Tugger Cart in Focus

Flat shelf cart - 1778 x 914 mm - Q-100-0985

1780 x 914 mm inch Flat Shelf Tugger cart. The shelf heights can be easily adjusted within 70mm intervals. This cart is equipped with drop pin hitch. The FlexQube core concept allows you to easily add or remove shelves to this cart easily on-site by your operators.

Modern production processes increasingly require flexible material flow concepts. The material flow must be effective, demand-driven and at the same time resource-optimised. Following this trend, the use of tugger train systems for material supply in manufacturing companies increases. There is more time and space available in workstations making part production more efficient.

Manufacturing operations are currently showing a clear trend when it comes to the practice of lean production: replenishment of assembly lines with production material by tugger trains.

This system facilitates lean concepts with a Just In Time (JIT) or Just In Sequence (JIS) supply of material. With this, FlexQube supports its customers in implementing modern solutions for production and flow of material.

There are many advantages in using tugger trains to provide material:

Throughout the supply processes, pre-commissioned load carriers can be moved to defined points to allow supply on demand. The trend towards small load carriers is ideally reflected by this method of transportation.

A single operator can supply material to an area of production alone without a forklift truck or pallet truck. This means fewer trucks in the fleet with cost savings for investment, operation and staff. The transport by tugger train within production areas is faster and safer than transporting pallets by forklift truck and handling time is reduced to a minimum.

Additional benefits are the simultaneous provision and removal of materials and empty load carriers, clearly defined transport routes without wasted empty journeys and a reduction of traffic in the production area.

With the tugger trains from FlexQube the noise level is reduced due to the high quality polyurethane casters used on the carts. The possibility to connect carts with multiple dimensions in the same train maximises the flexibility of your operations. In addition to this, a tongue and hitch tugger train system makes it possible to disconnect a cart and place it on either side in the aisle. You can go left or right, and with fixed casters at the centre of the cart it will pivot around its own central axis, making the turn extremely easy even with heavy loaded carts.

With no need to connect a cart to a mother frame, the carts can be made with a very low profile, so called low riders or lowboy carts. That means you can stack more totes and bins on top of each other and keep them in the ergonomic zone for the operators.

FlexQube has an official sales and distribution agreement with STILL GmbH as well. Within this agreement, FlexQube delivers trolleys to the user-friendly “LiftRunner” system that allows the trolleys to be pushed into the trailers at floor level. In transit, the trolleys are raised hydraulically or pneumatically so that only the larger wheels of the “LiftRunner” trailers touch the floor. This reduces noise and decreases the wear and tear of the trolley wheels which cannot get caught anywhere and therefore increase the service life. The trolleys are automatically locked by locking pins to prevent them from rolling sideways out of the trailer.

At the destination, the operator can simply pull the trolleys out of the train; an “ejector” activated by a foot lever compensates for the initial inertia of the trolley. The trains can be loaded or unloaded from the left or the right, because the couplings in the “LiftRunner” trailers allow loading into the train in both directions.

FlexQube carts can be used both indoors but also to some extent outdoors depending on the weather conditions in the geographic location. The carts work well even on slopes with the heavy-duty toe bars that safely connect the carts.

FlexQube tugger train carts help improve your company’s material flows to increase profitability and efficiency.

The modular and flexible concept is the basis for modern material supply applications via tugger train and includes platform trolleys and pallet trucks. All the tugger carts can be equipped with state-of-the-art tongue and hitch systems developed by FlexQube, including the wire release tow bar solution which is an ergonomic revolution for operators driving tuggers and line feeding.

Pivoting tugger carts require minimal effort to move manually and have a near zero turning radius while being pushed by hand. This enhances manoeuvrability in narrow aisles and dead-end pathways.