12 June 2019

13 more reasons than just the SEVEN to go with the FlexQube concept!

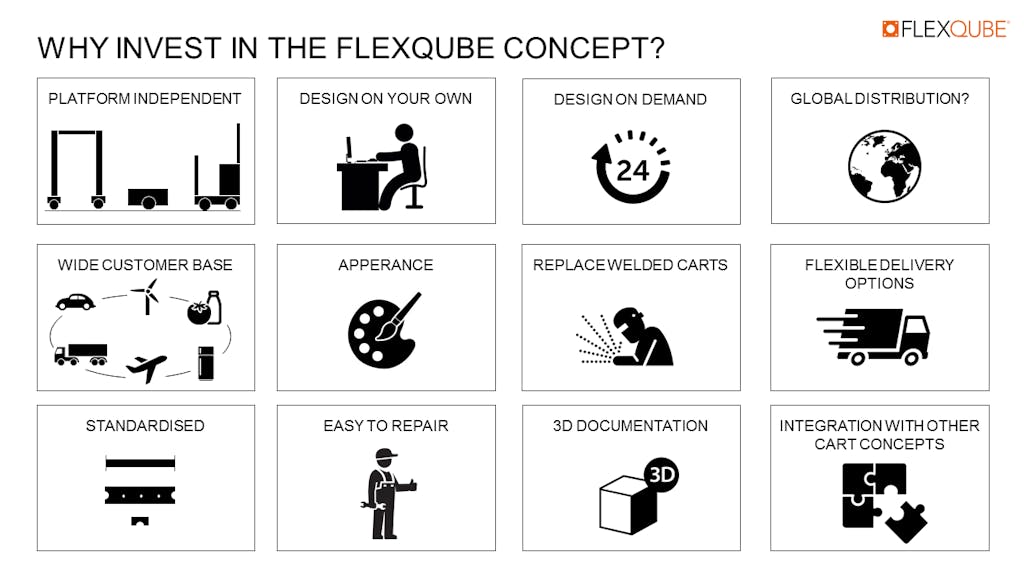

The FlexQube concept is built upon a standard that uses 7 as the common number. You can read more about that here. But there are more to FlexQube than just this number. I will emphasize 13 other things that makes our offering unique in the world of material handling equipment.

- Independent of platform – Our applications can be used together with a lot of different tugger train solutions, mother-daughter applications, AGVs, be equipped with a tow bar or pushed manually. With the standard interfaces appearing throughout the solutions it is easy to adapt to the different methods of moving the carts.

- Transfer between methods – Since there is a built in flexibility with the hole pattern, you can easily dismount e.g. the tow bar and instead add an adapter for e.g. an AGV solution. That means you are not bound to a specific system, tugger train brand, forklift truck or method of moving the carts but can instead focus on the functionality of the carts themselves and modify the cart to the changes in your intralogistics operations.

- Quick and easy design process – With the DesignOnDemand™ process where you as a customer define your requirements in a web meeting with one of our skilled designers you will watch your solution evolve in real time. The standard building blocks makes it possible for the designer to quick and easy put together the perfect solution, customized for your needs. In addition to that, our Solutions Library™ contains hundreds of already built carts and racks for you as a customer to use as reference and inspiration.

- Global manufacturing footprint – With manufacturing sites both in Europe and in USA we make sure that you as a global customer with worldwide operations gets the same service, the same solutions and the same quality products that look exactly the same on both continents.

- World leaders develop our company, not just one single company – With the world’s most prominent customers in several industrial segments, including the ones seen as the leaders in lean production, we get inspiration and feedback that ensure our company to move forward and deliver innovation, market-leading products, and solutions.

- Design standard that can be customized – With modular building blocks and futuristic design we know how to make a factory floor look good and inspirational. We can adjust the colors of the solutions to the customers’ company standards.

- More light weight than welded but still robust enough – Using a special high strength steel and protrusions that doesn’t affect strength, our solutions are more light weight than welded competitors. Our system is perfect for flat deck tugger carts or other industrial shelf- or kit-carts. Serving a range of needs between tube and joint applications and more heavy duty welded ones, the FlexQube concept has found its sweet spot in the market. Too heavy to lift by hand or too heavy to move by hand – go FlexQube.

- Choose assembly or unassembled – This choice gives you the freedom to save a lot of money on transportation costs or utilize your own internal resources to do the assembly. The delivery comes with an instruction on how to put together the solution. Or if you want to just do the plug-and-play setup, we will deliver a completely assembled unit to you.

- A standard but not a limitation – All of our basic components comes in length increments of 70 mm. Just like LEGO® bricks, it makes sure the structure will fit together. It also enables you to set a standard for your applications and not have the complete freedom to build just any size which could lead to a plant filled with different applications, impossible to use for planning of new assembly layouts or to copy for other production sites.

- Service and spare parts made easy – If damage occurs to an application it is easy just to swap it for a new piece. No need for cutting, welding or painting. Just plug and play.

- Everything documented – All applications developed in a design software or purchased from our Solutions Library™, comes with a 3D model which makes it easy to keep track of spare parts and maintenance. The delivery will include a documentation with maintenance plans and measurements of the solution. In addition to this your spare parts can be found on our web page.

- Design yourself – The DesignOnDemand™ process above is just one way of developing the application. You can also utilize our components library yourself. Work in any CAD software or even in the cloud based software Onshape to design your customized solution; something we call Design4All™. You can schedule a Design4All meeting for free with our Design Manager that will help you get started, just email. You will be amazed by how easy it is to do the design with our concept.

- Integrate as you wish – Many of our customers are already users of the tube and joint systems, but some of the best and most well-suited applications for their needs we have seen has been an integration between the FlexQube concept and a tube and joint system. Just let each system do what it’s best at. We encourage this!