5 Must-Have Warehouse Material Handling Equipment for 2020

Last Modified: 2022.08.29

Warehouse material equipment constantly experiences a growing demand. This, because there is an increased interest to replace outdated machinery with new, automated material handling systems and robots – especially automated guided vehicles and conveyors. In the US alone, the market size of material handling equipment is projected to reach US$156 Billion by 2026.

Knowing what new warehouse material equipment your facility needs can be difficult. Therefore, we provide our best recommendations for you!

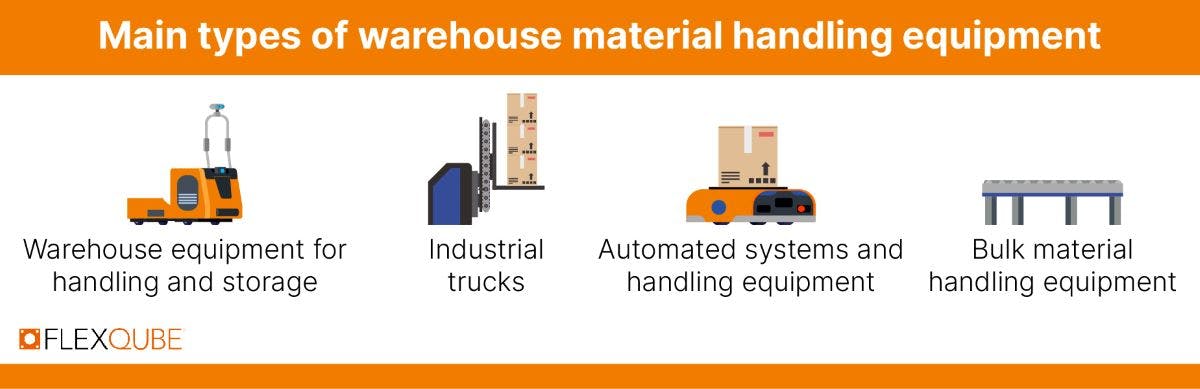

Different types of warehouse material handling equipment

There are different types of equipment to move materials around in your warehouse, facility, or across a shop floor. It is possible to categorize the equipment into four main categories:

01. Warehouse equipment for handling and storage. Today, many warehouses are in the process of upgrading their material handling solutions because forklifts don’t seem to be enough to handle material transport requirements. Tugger carts and tugger trains are the most popular JIT solutions for replacing forklifts in warehouses and manufacturing firms.

02. Industrial trucks. These include forklift trucks, telescopic handler forklifts, and electric forklifts. With the adoption of Artificial Intelligence more and more industrial trucks will be connected and automated.

03. Automated systems and handling equipment. This segment of material handling equipment will steadily increase with the adoption of automated material handling equipment like AGVs, AMRs, and robotic delivery systems in general.

04. Bulk material handling equipment. This equipment is designed to handle dry materials which are powdery – like sand, clay, or cement. One of the most important equipment types in bulk materials handling is a conveyor belt.

One key to achieving warehouse efficiency is finding material handling equipment that is adapted to your facility, such as your aisles, operators, materials, etc.

Here at Flexqube, we know how quickly processes and materials in a warehouse can change, and we have developed a concept that matches this reality. By creating modular and robust equipment that enables customization, you get to choose which transportation method you want or need to use, and in which size.

We have, therefore, categorized the must-have warehouse equipment depending on what load you are transporting.

5 must-haves in warehouse material handling equipment

When choosing material handling equipment for your warehouses, you have to consider the weight of the load and usage of the equipment. The five must-haves in warehouse material handling equipment, for all types of loads, are listed below.

01. Tugger carts

Tugger carts are material-handling carts that have the option of being towed by a fork truck or tugger but can also be manually transported by an operator.

The option of using a tugger cart in a tugger train cart allows for the picking of multiple orders regardless of their weight. Tugger trains are also safer options to use with a tugger cart when compared to using a forklift.

This piece of material handling equipment is an excellent option for transporting heavy equipment across the shop floor. With tugger carts, you get the added advantage of driving them manually or in a tugger train system.

The FlexQube tugger carts are designed to match the dynamic and constantly changing environment in which material handling currently happens. Materials are constantly changing, which makes it difficult for purchasers and lean engineers to manage their stock of material handling equipment. The FlexQube concept lets you purchase tugger carts now, but they can then easily be altered in the future.

02. Standard pallet carts

The standard pallet cart is another great choice for moving large assemblies and an excellent way to transport materials efficiently across the shop floor. Like a tugger cart, items on the pallet cart can be transported manually by the order picker or be attached to a tugger train.

The cart comes with swivel casters, which add to its mobility and provide a solid support base. You can choose to use either the tugger cart or pallet cart for heavy-duty material handling in warehouses.

The FlexQube concept allows you to design your pallet carts to match your exact needs easily.

For example, if you are looking for a manual push cart, but then need to add a tow bar, it is as easy as bolting on a FlexQube tow bar to your push cart, and it becomes tuggable. This means you’re getting proper equipment with less need for equipment storage – thereby saving warehouse space.

03. Flow shelf carts and flow racks

Flow cart or rack options are designed to transport different items across the shop floor at the same time. These carts come with multiple shelves or racks that also aid the arrangement of the materials being transported.

The angular orientation of the shelves and racks also simplifies the task of taking items off this piece of material handling equipment. In terms of handling, flow solutions can be equipped with tires for transportation; without tires they are a great piece of storage equipment.

FlexQube provides innovative order picking and carton flow solutions using our modular and flexible concept – it will give you sturdy, robust flow rack solutions that will last longer. By implementing flow racks and other such equipment, you can improve space utilization save floor space, as well as upgrade ergonomics at the point of use.

04. Tube carts and kit carts

On shop floors where tubes and wires are needed for everyday operations, tube carts are recommended. They offer hangers for hanging these items as they are transported from one workstation to another. Kit carts, on the other hand, are a more versatile option than tube carts.

These carts consist of shelves for tools and kits, as well as hangers that support the transportation of tubes. They are also equipped with support handles and swivel tires, which aid manual transportation.

All FlexQube carts are designed and constructed with high-quality steel, so they have a much higher load capacity in comparison to more traditional tube and joint systems. By gathering information about batch sizes, sequence, a mix of parts, and other parameters, FlexQube can help customers design and adapt the perfect kit-cart.

05. A mother-daughter cart

The mother-daughter cart is a beautifully partitioned piece of material handling equipment that simplifies the transportation of different loads.

The mother-daughter cart can come in a 4-in-1 configuration, going as far as an 8-in-1 configuration. Depending on the details of your facilities’ milk runs, you can choose a configuration that helps streamline the picking process – and pickers achieve their goals with ease.

The mother-daughter cart concept with the FlexQube system can be integrated with many of the different mother-daughter systems on the market – including the STILL Liftrunner E-frame, B-frame, or C-frame system. While other companies provide standard-sized mother frames and solutions, FlexQube can offer custom-made designs using the LEGO® inspired building block system.

Modular and customizable warehouse material handling

The five storage and handling equipment options listed here are designed to meet diverse warehousing requirements. The way you transport and store materials can easily be upgraded by applying engineered systems that take advantage of suitable material handling equipment.

For more specific warehouse transporting needs, you can choose to customize your material handling equipment or think about warehouse automation. Have your material handling equipment designed by experts in automated storage and material flow.

Our design team can help you build modular material handling equipment for your warehouses. Just reach out and tell us about your project. We’ll get back to you and our team will help you find the right solution for your facility.