FlexQube’s Top 5 Kit-Carts

Last Modified: 05.03.2020

The FlexQube design and concept favors creating kit-carts, and our designers take a lot of joy in creating new and interesting carts.

We have been able to help many customers with how they assemble and present their materials by helping them take advantage of our flexible system. Our cart designs can be separated into two different categories, material presentation, and material transportation.

Kitting comes under the material presentation side of our carts. It is the process of collecting different materials and components and placing them in a “kit”, which would be one of our kit-carts. These kit-carts are then placed along the assembly line, where operators can more efficiently access the variety of parts and components.

Below we have outlined FlexQube’s top 5 kit-carts.

70 x 41 Inch Kit-Cart – Q-100-0650

This large kit-cart is used to presenting and transporting heavy-duty materials. This cart is equipped with a drop pin and hitch tow bar, so it doesn’t have to be used for purely material presentation. It can be towed within a tugger train set-up directly to the assembly line. This cart is equipped with reinforced steel hangers, which are designed for placing heavy hanging components. It also comes with four flat shelves on the right-hand side of the cart for placing bins, totes, and boxes.

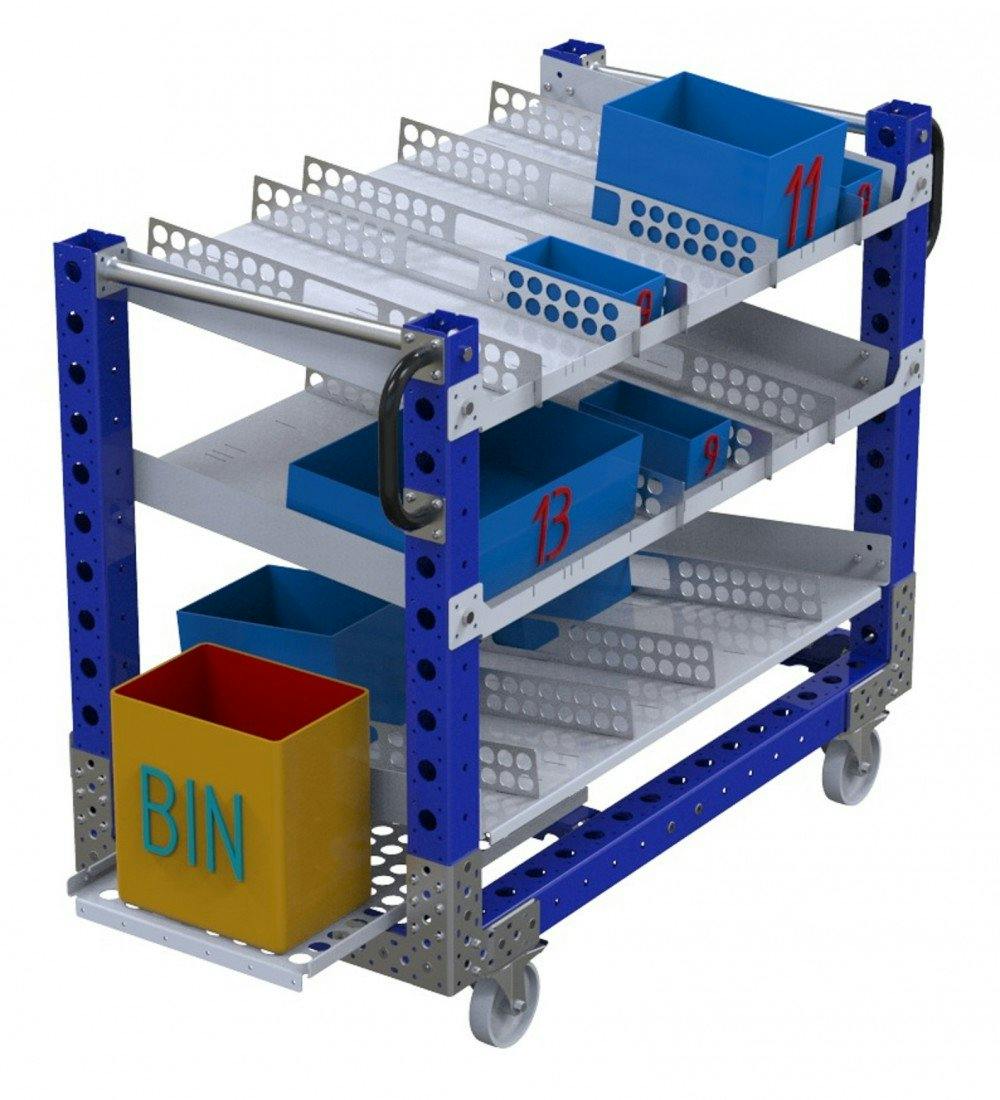

Line Side Flow Shelf Rack – Q-100-0457

This shelf cart is designed for being placed right at the assembly line with the operator. It is equipped with dividers for sliding bins, totes, and boxes in, and it works as a flow shelf. The two top shelves are angled towards the operator, making it easier to access the materials, and the bottom shelf is facing away, making it easier for replacement. This cart comes equipped with two handles for manual pushing from the warehouse to the assembly line.

91 x 69 Inch Windshield Cart – Q-100-0661

This cart was initially designed for transporting windshields from the warehouse to the assembly line. However, this cart can also be used for transporting oversized panels to the assembly line. It is equipped with an ergonomic handlebar to make it easier for the operator to push the cart and materials and a floor lock brake to secure the cart and materials in place.

Tool Cart with Telescopic Shelves – Q-100-0026

This tool cart is ideal for the assembly line. The telescopic shelves make it very easy and efficient to get to the tools and materials which can help eliminate “search time” along the production line. This cart is also equipped with a floor lock brake so it can be secured in place. This cart can also have a shadow board added to the top structure, from which tools can be hung.

1960 x 910 MM Tube Cart – Q-100-1157

This 1960 x 910 mm tube cart is another example of how flexible you can be with the FlexQube concept. This cart is designed to present different hanging materials and tubes easily. It is equipped with two polyamide casters with attached brakes to secure the cart in place and two fixed polyamide casters. It comes with a handlebar to make it easier to transport around the assembly line.

Using kit-carts can provide quite a few advantages to your facility and operators. The more customized your carts are to your working methods and your materials, the more efficient your workflow and processes will be. Using kit-carts as one of your primary material feeding workflows reduces the time operators, and handlers spend looking for materials and components. However, the most prominent advantage many of our customers see when turning towards kit-carts is the amount of space that can be saved along the assembly line. Using kit-carts eliminates having assemblers boxed in by parts and components. Combining kit-carts with a just in time means your assemblers will be delivered what they need, when they need it, which obviously makes for a very efficient system.