Standardization and Flexibility hand in hand

The need for flexible trolleys has never been more obvious. Increasing number of products, shorter product life cycles, more parts to handle, and shorter lead times in product development projects are some of the drivers for this.

On the other hand, the need for standardization has never been more obvious either. Nowadays manufactures have global industrial footprints, with regional plants supplying local markets with the needed products. In order to secure quality, new product implementations and manufacturing all around the world, there must be clear standards describing the best way of working.

But one thing is clear; standardization can´t mean that exactly the same solutions are used everywhere. The needs will be completely different due to differences in volume and mix of products at different plants and regions.

So how can you create customized solutions, such as trolleys, and at the same time work in a standardized way?

Children has done it for decades: They have e.g. played with LEGO®!

FlexQube cart at Eberspaecher Exhaust Technology

Millions and millions of applications has been created all around the world using the standardized bricks. The LEGO® bricks can be assembled and connected in many ways thanks the famous interface. The distance between the interfaces are always the same, which allows bricks with different lengths to be combined. And the bricks can be reused over and over again, from generation to generation.

LEGO® is the solution for children. FlexQube is the solution for the manufacturing industry. FlexQube® is the future way of handling complexity, in a standardized, simple and fun way.

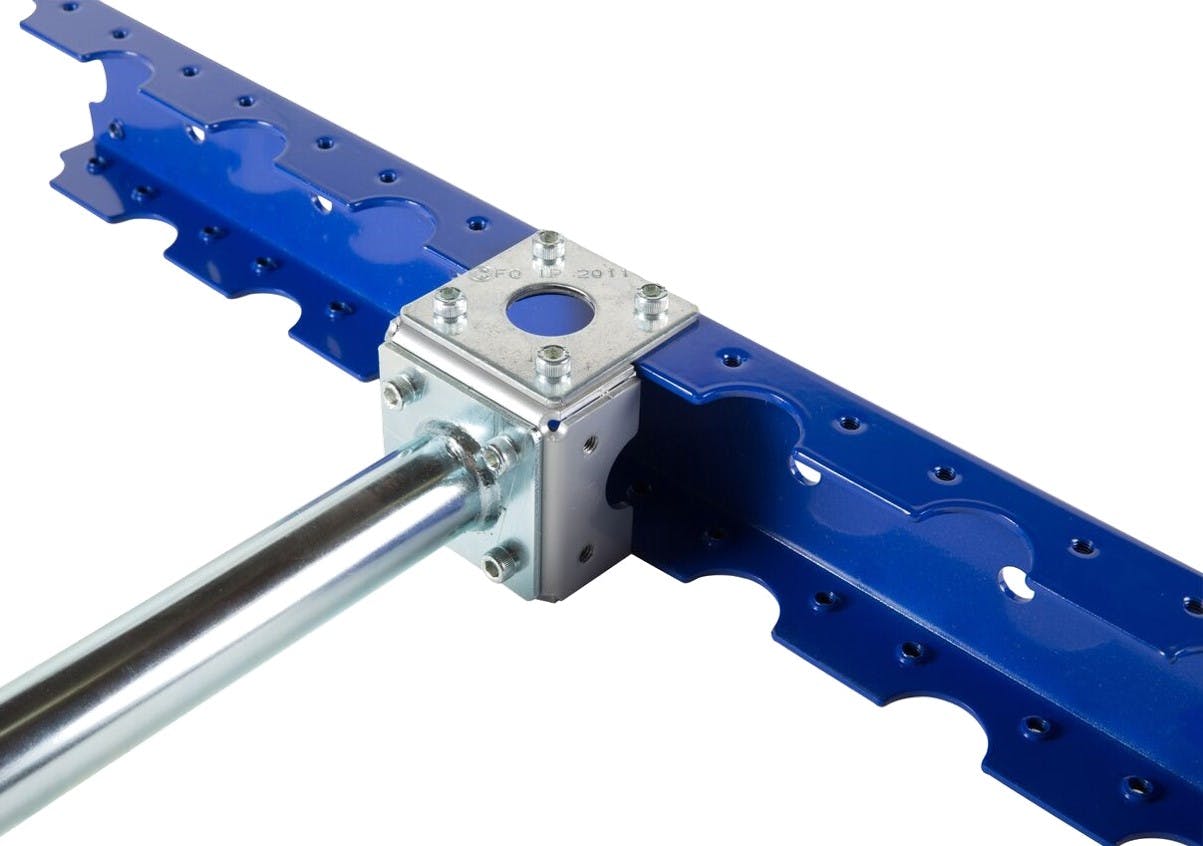

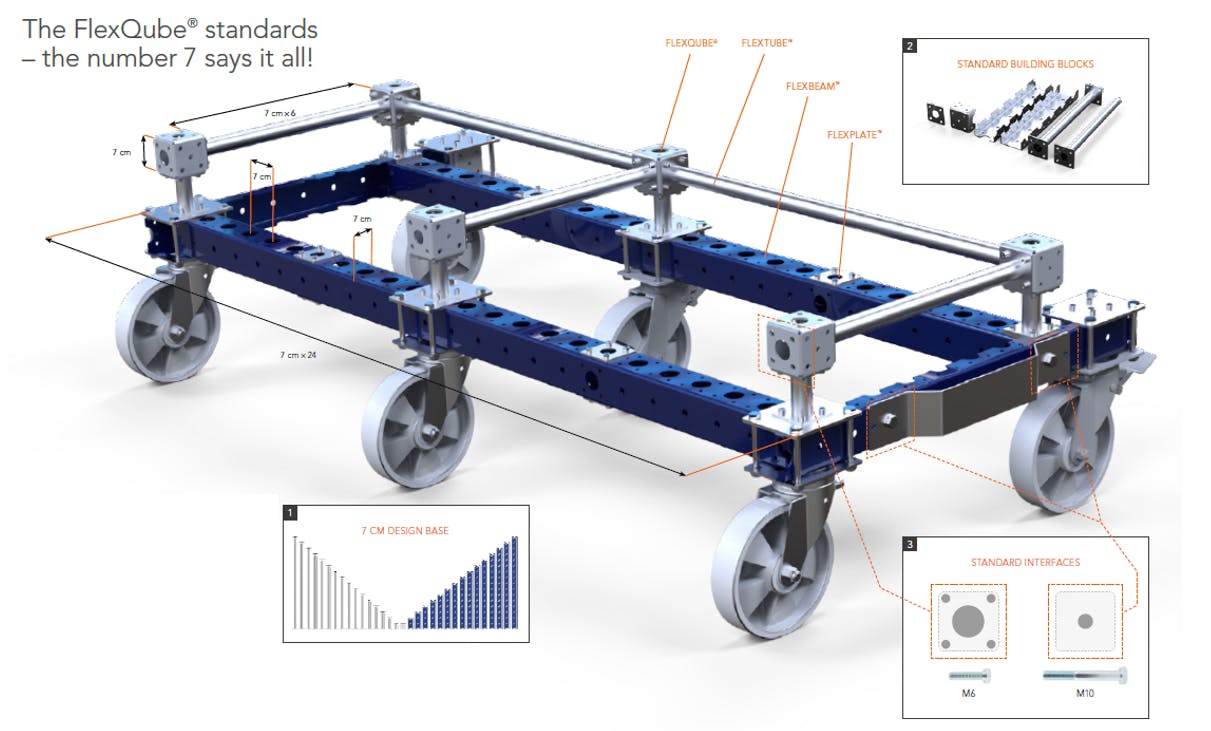

The bricks in the FlexQube concept is represented by the FlexQube™, FlexBeam™, FlexTube™ and the FlexPlate™. Innovative, smart, robust and standardized modules that give endless possibilities for the users. I recommend you to take a look at the FlexQube Solutions Library™ to get inspired and see what others have created.

7 is a magic number describing the FlexQube standards in a good way. The longitudinal modules FlexTube™ and FlexBeam™ are available in length intervals of 7 cm. The width of the components is 7 cm, and the distance between the FlexQube™ interfaces is always 7 cm. If you want to learn more about the LEGO® inspired concept and the standards. Click here to learn more or download our Product Catalog here.

With the FlexQube concept, flexibility and standardization will go hand in hand.

Qube it!™

Per Augustsson

CTO, FlexQube

Read Pers other text about a fork-lift free future here! Read Pers text: Do you have a screw loose? here!