Top Trends in A to B Warehouse Transportation for 2020

2020 signals the end of another impressive decade in material handling, which drives the manufacturing and warehousing industry.

Within this decade, advancements in A to B warehouse transportation, as well as shop floor material handling processes has led to the creation of an industry with a market size of $194 billion. The factors responsible for this impressive growth are centered around the integration of emerging technology in warehouse transportation and the use of data.

From 2010 through 2019, businesses within the manufacturing, warehousing, and facility management niche embraced the use of data. This led to an increase in how data is captured across the shop floor and its use as a business insight tool to curtail waste and other challenges these industries faced. Now, at the cusp of a new decade, it is only right to outline the factors and trends in A to B warehouse transportation manufacturers must know to keep their competitive edge.

The Automated Warehouse

Automation is no longer a new concept in material handling or warehouse transportation as its benefits have been continuously highlighted throughout the 2010s’. And today, with market size of $5 billion, automation is here to stay for the long haul. Thus, even if it has been included in previous trends, it still is a worthy mention with a focus on its increasing adoption rate within SMEs.

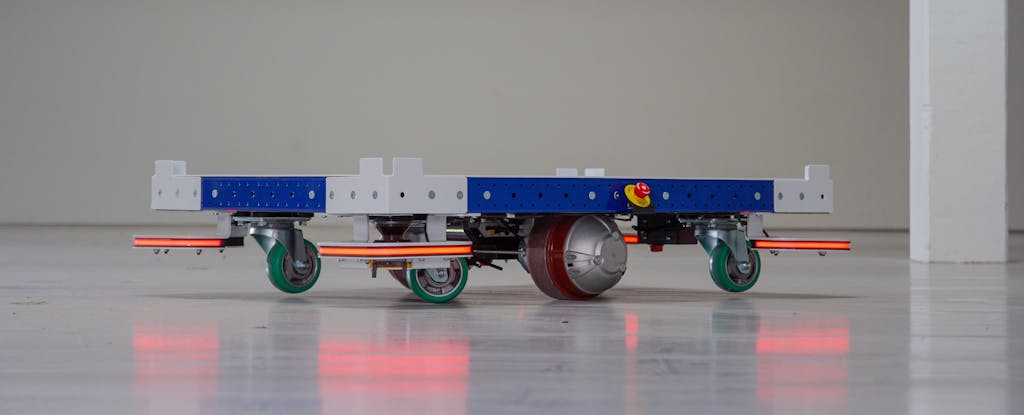

The new year would be defined by the continuous work of original equipment manufacturers to reduce the cost of automating warehouse transportation machines, including autonomous guided vehicles (similar to our eQart), and robots. Today, automating A to B warehouse transportation is still largely an initiative pursued by large enterprises due to purchasing costs. But like the growth from expensive mainframe computers to the personal computer, innovation in automated equipment is expected to drive down the cost of automated warehouses. Thus, providing SMEs with an entry point into automating transportation in smaller warehouses.

IoT for Transportation

Statistics put the number of sensors and IoT devices currently being used across the globe at 75 million, and this number is expected to keep growing by 2020. Within this number, a chunk of the sensors being used today is integrated into manufacturing processes happening across warehouses to capture data. While these data sets have been used to enhance productivity through predictive maintenance and machine monitoring, their potential to change A to B warehouse transportation has not been fully harnessed.

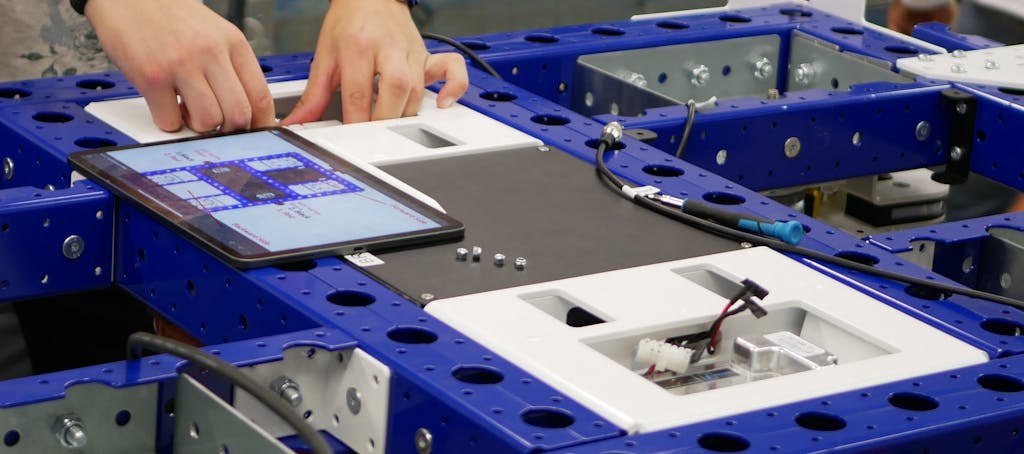

By next year, this is expected to change as more facility managers integrate IoT into better understanding transportation issues and their effects on the manufacturing or warehousing process. Thus, many warehouse transportation equipment is being equipped with smart edge technologies making them IoT devices of their own. Plugging an IoT-capable material handling equipment into a centralized network will enhance shop floor transportation and provide more insight into traditional A to B warehouse transporting operations.

Want to stay up to date? Subscribe below

The Introduction of Edge Computing

Edge computing refers to the deployment of data-handling activities and network operations towards independent sources of data capture, storage, and analysis. In warehouse transportation, this means integrating material handling equipment with computing resources, which allows them to make decisions in real-time.

How is this different from using robots for warehouse transportation, you may ask? The answer is with edge computing; even dumb material handling equipment can be equipped with computing capabilities. Thus, slapping an edge computing device on a flat cart can enable the collection of data from it and even automate its movement directions. Edge computing can also be used to capture data such as coordinates and patterns from the deepest parts of warehouses to understand shop floor transportation or traffic better. These features mean brownfield warehouses can automate transportation processes without having to change every legacy infrastructure within them.

Increased Investments in warehouse Management Systems

For the data collected to be useful in enhancing A to B warehouse transportation, they must first be analyzed. Thus, warehouses will have to take advantage of management systems, including centralized databases, to accurately deliver an automated shop floor. Location systems and automation solutions are also examples of some of the management systems manufacturers will have to rely on to deliver the automated warehouse.

For those who ask how warehouse management systems will remain compatible with edge computing, the answer lies in the application. While edge computing brings real-time computing to dumb or legacy transportation equipment, it is essential to note that it works with only the data necessary for specific processes.

An example is when an edge computer collects coordinate data and analyzes it to deliver real-time movements to equipment. The analyzed data and other information collected but not needed for coordination, such as shop floor images can be sent to a warehouse management system. These data can then be further analyzed to increase productivity levels within warehouses.

Adopting Digitally Transformation

In its purest form, digital transformation refers to the representation of physical objects and processes in digital form. Here physical processes refer to complex systems such as an entire A to B warehouse transportation network and the assets within them into a digital environment. The developed digital model is then used to automate, troubleshoot, and enhance the transportation operations within a shop floor.

Digital transformation creates one of the appropriate options for achieving true automation when compared to warehouse management systems. An example is the use of digital twin technology to recreate entire warehouse systems, map out interrelated relationships, and variables that affect warehouse transportation. The digital twin can then be used to simulate different situations that lead to downtime and provide accurate answers to eliminating these challenges. It also provides an avenue to create real-time schedules to ensure transportation timelines are optimized to meet shop floor needs.

The digitization of warehouse transportation is already ongoing, and 2020 will see further integrations of digital twin technology and simulation to deliver real-time scheduling and automation.

Getting Ready for 2020

A to B warehouse transportation is currently undergoing a paradigm shift driven by emerging technology. This is why automating transportation operations, robotics, edge computing, and security are the raves of the moment. With 87% of online shoppers stating delivery timelines as a top priority, the need to speed up A to B warehouse transportation to meet demand is at an all-time high while manufacturers and warehouse managers are feeling the heat.

To stay ahead of the increasing demand of your customers, as well as, remain competitive with the competition, it is important to stay abreast of these highlighted trends. Although the process of integrating them into your shop floor may seem herculean, you can learn more about the best options for your warehouse by contacting our experienced engineers at FlexQube.